Request a quote for custom spring energizers, shims, and more.

About Maudlin Products

Our Maudlin Products location is built on a commitment to quality, craftsmanship, and meeting the most demanding industrial requirements. Offering 24 hour turnaround on all stock items, and one of the fastest turnaround times for custom products in the industry, Maudlin knows what it takes to ensure your equipment is protected and is dedicated to ensuring your schedules are met.

Compliance

Certifications

Industries We Serve

Our Manufacturing Services

-

MW Components offers prototypes or sample parts for a variety of custom components including springs, fasteners, bellows, couplings, and other precision metal parts. We also offer rapid prototyping for select components, with shipping in as little as one week.

-

Milling

MillingMilling is accomplished using computerized controls to operate motorized cutting tools.

-

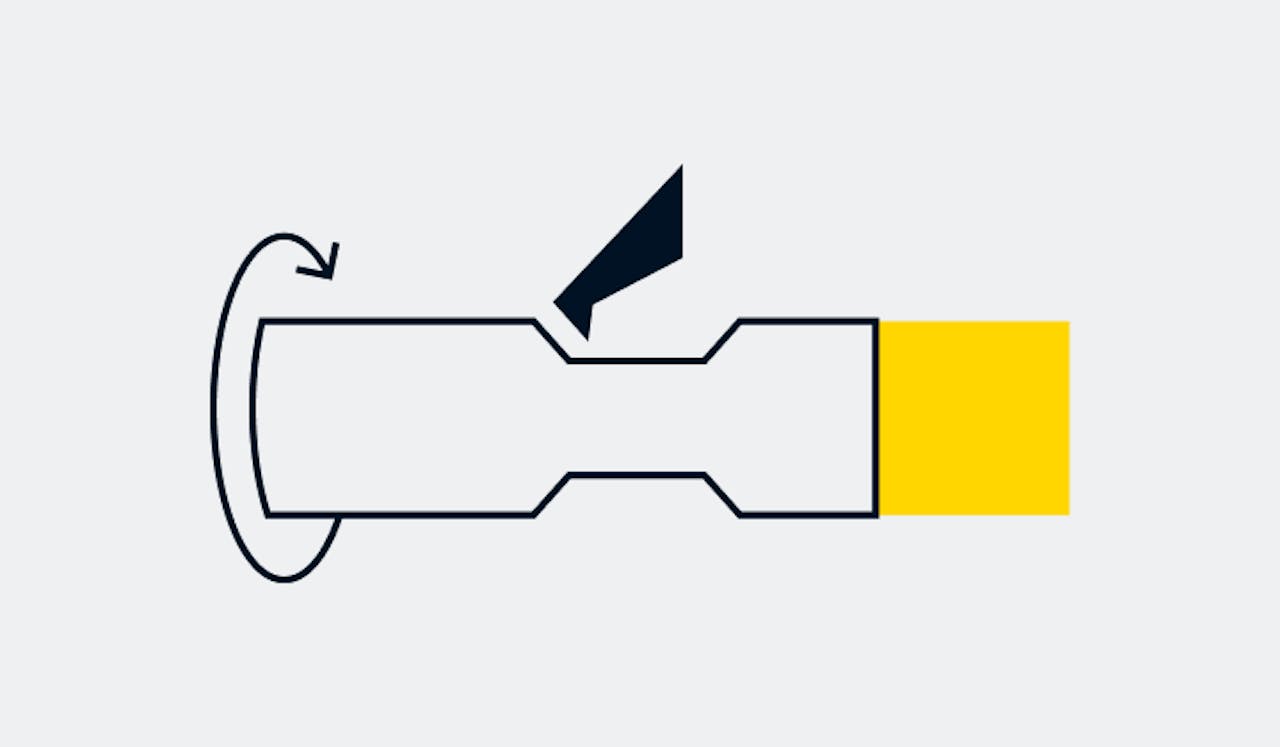

Turning

TurningThe manufacturing process known as CNC turning involves feeding metal bars into a machine and applying one or several tools that gradually shape the material into the desired form. Examples of capabilities that our precision turning centers have include Swiss lathe machining, threading, tapping, cross drilling, end or side milling, and broaching.

-

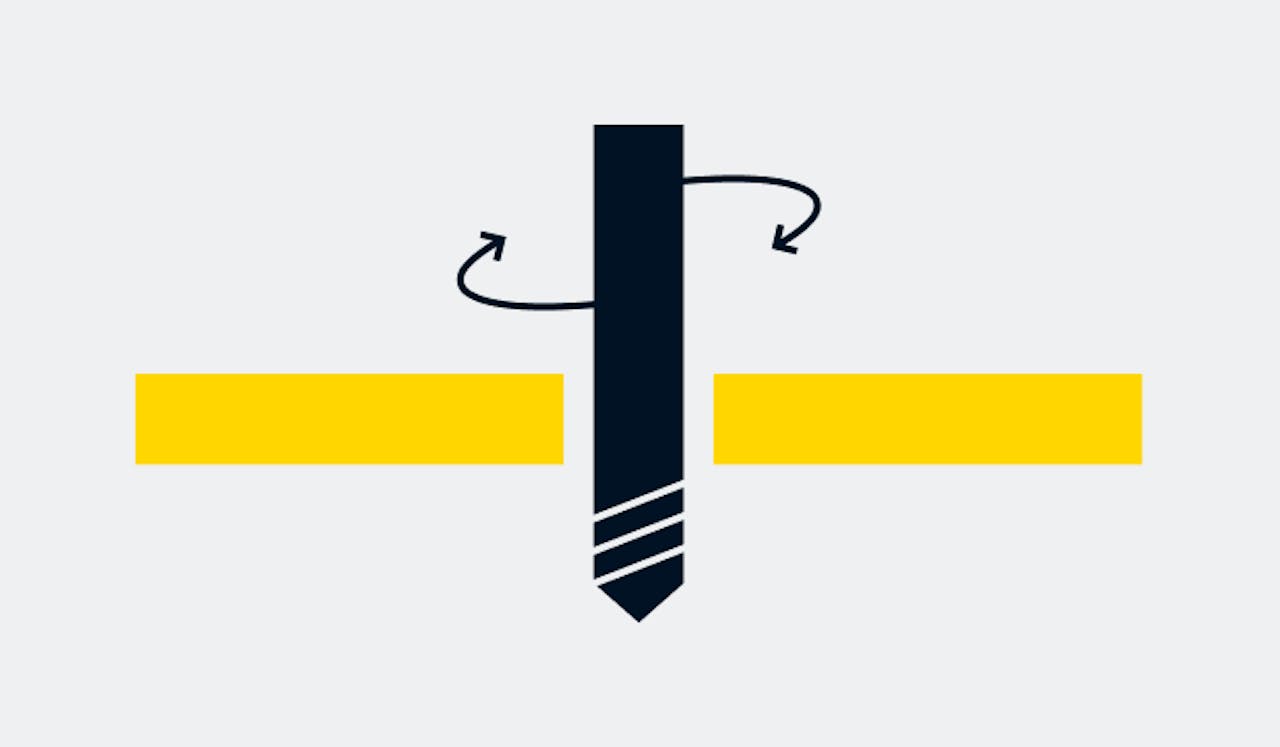

Drilling

DrillingDrilling is the process of cutting one or several holes into a material using a machine equipped with a drill bit.

-

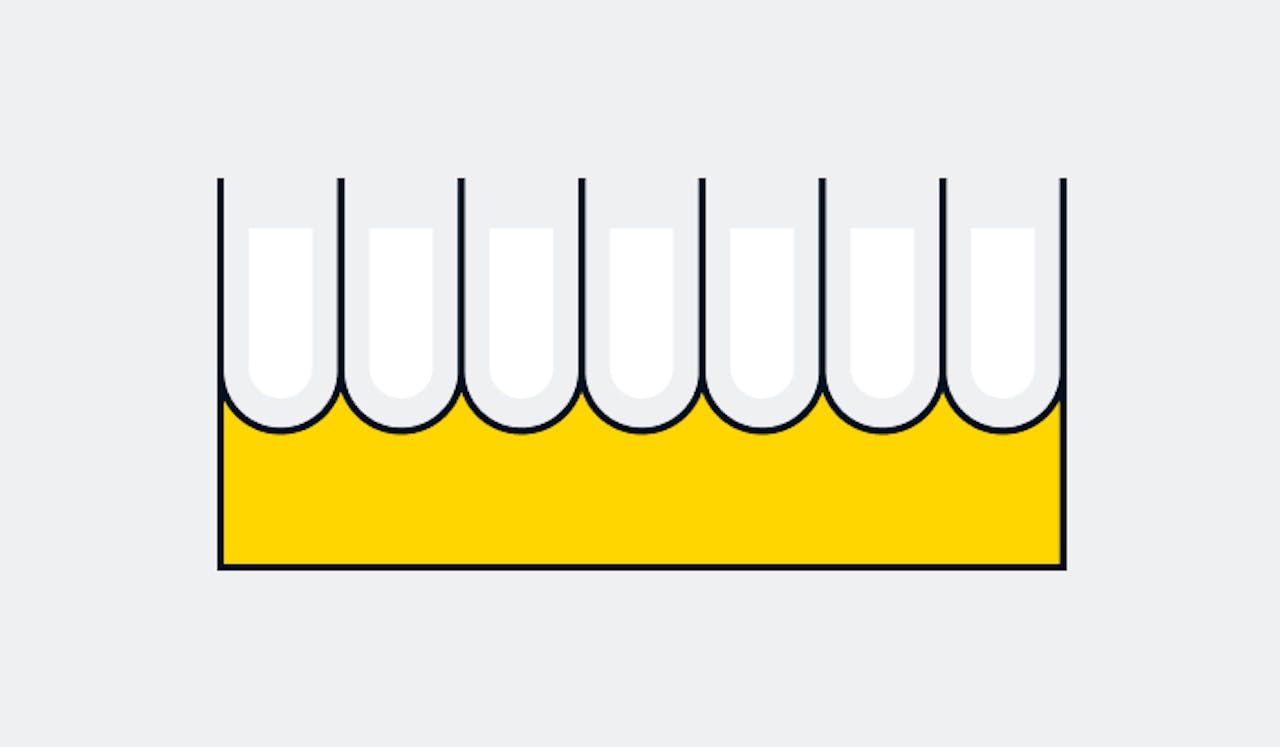

Honing

HoningHoning is a machining process used to improve a metal’s exterior finish or enhance the geometric form of a surface. Honing is accomplished by applying an abrasive grinding wheel or stone to shape the metal along a designated path.

-

MW facilities use several methods to stamp or form sheet or strip metal into a desired shape. Some examples include stamping and fourslide. Stamping uses a die and applied force to create a product, where fourslide uses multi-slide technology to bend and manipulate metal into a desired form.

-

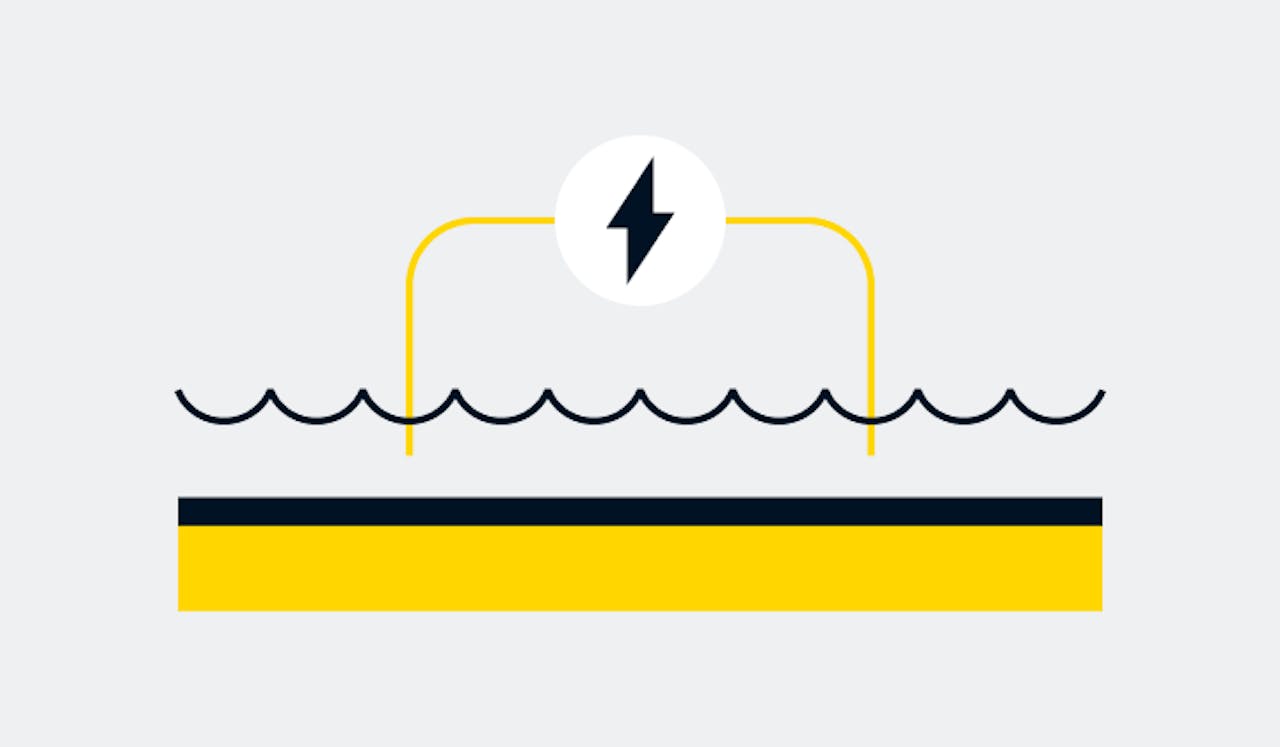

5 axis waterjet cutting is a CNC machining process used in manufacturing to cut hard surfaces. Water is mixed with abrasive material and propelled in a high-pressure stream, cutting through various difficult materials, including stone, ceramics, glass, metals, etc.

-

Laser optics and computer software direct high-powered lasers, making precision cuts in materials using complicated patterns.

-

Wire EDM cutting forms metal components into complex structures using electrical discharges. Wire EDM machining produces extremely precise cuts in intricate shapes, creating sharp corners and difficult angles.

-

We perform precision sharpening and CNC grinding services including electrochemical grinding in the production or finishing phase as needed for your intended application.

-

Laser welding or laser beam welding is a joining process used with metal or thermoplastics through the application of a directed laser.

-

Soldering

SolderingSoldering joins two or more materials together by filling the joint between the two with a melted filler metal. Unlike traditional welding methods, soldering does not require melting the original materials.

-

Anodizing

AnodizingThis is a passivation process used to thicken the natural oxide layer on the external surface of metal components. This offers added protection for aluminum alloys, titanium, zinc, and other metals.

-

Outside of hardening and tempering, we offer a variety of other heat treatment options to ensure your desired ranges are reached for cycle-life, toughness, and resistance to environmental forces.

-

Plating

PlatingPlating is a manufacturing process where a thin coating is applied to a component’s surface through chemicals or electric current (electroplating).

-

Do you need specialized packaging? We work with your teams to determine the best way to build and package your products to ensure efficient assembly with your existing components.