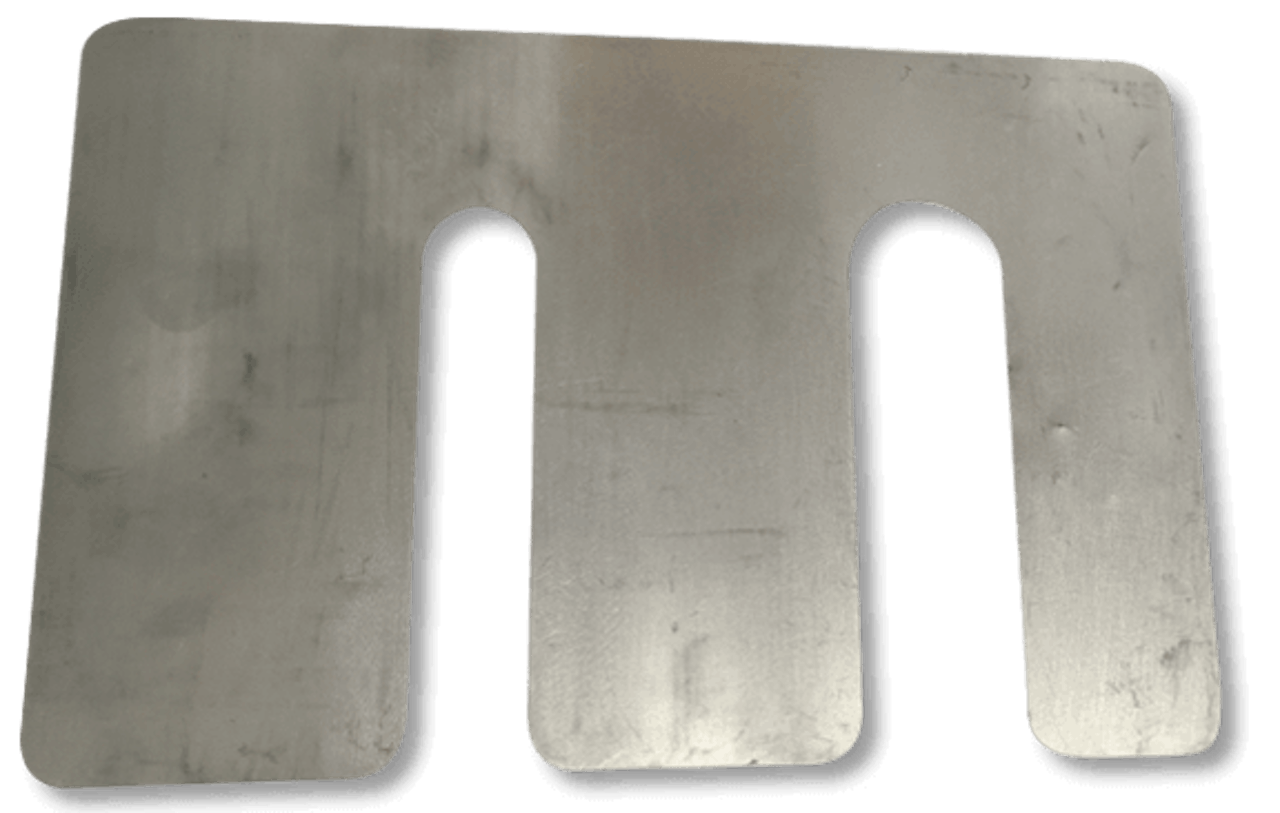

Weg Motor Shims for Metallic Bases

Weg motor shims are used to create a flat surface under motor feet to keep from deforming the frame.

How Are Weg Motor Shims Used?

Metallic bases must have a flat surface under motor feet in order to avoid frame deformation. The bearing housing surface should be so determined that under the feet of the motor one can place a weg motor shim of approximately 2mm thickness.

The motor should not be removed from their common metallic bases for alignment; metallic bases should be leveled on the actual foundation. When a metallic base is used to adjust the height of the motor shaft end with the machine shaft end, it should be leveled on the concrete base using weg motor shims. After the base has been leveled, foundation studs tightened, and the coupling checked, the metal base and the studs are then cemented.

CUSTOM MANUFACTURING

Custom Motor Shims

No matter the size of the job or type of customization, MW Components is here for you. Our experience combined with our state-of-the-art facilities and our team of manufacturing and engineering experts ensures that the right part is produced for the right application time after time. We even offer optional added services for your convenience, whether you need help with design, prototyping, tooling, or inventory management.

Contact us for custom quote information to send us your specs or begin production on custom parts.

Alignment / Leveling of Weg Motor Shims

The electric motor must be accurately aligned with the driven machine, particularly in cases of direct coupling. An incorrect alignment can cause bearing damage, vibrations, shaft breaking, and brush sparking. The best way to ensure correct alignment is to use a dial indicator placed on each coupling half, one reading radially and the other axially. In this way, simultaneous readings can be informed and one can check any parallel (figure 8) or concentricity deviations (figure 9) by rotating the shaft. The dial indicator should not exceed 0.05mm. If the operator is sufficiently skilled, he can obtain alignment with a clearance gauge and a steel ruler, providing that the couplings be perfect and centered (figure 10).

A measurement at 4 different points of the circumference should not give a reading difference larger than 0.03mm. Figure 8 – Angular Clearance (Parallelism).

On the alignment/leveling using weg motor shims, it is important to take into consideration the effect of the temperature over the motor and driven machine. The different expansion levels of the coupled machines can modify the alignment/leveling during motor operation.

After the set is perfectly aligned either at cold or at hot, the motor must be bolted, as shown in figure 11. There are instruments that use visible laser rays added by specific computer programs that can perform and ensure high precision alignment.

Have Questions?

Talk with our experts today and let us help you figure out the best solution.