Request a quote for custom spring energizers, shims, and more.

Maudlin Products

Spring Energizer & Shim Manufacturing Specialists

-

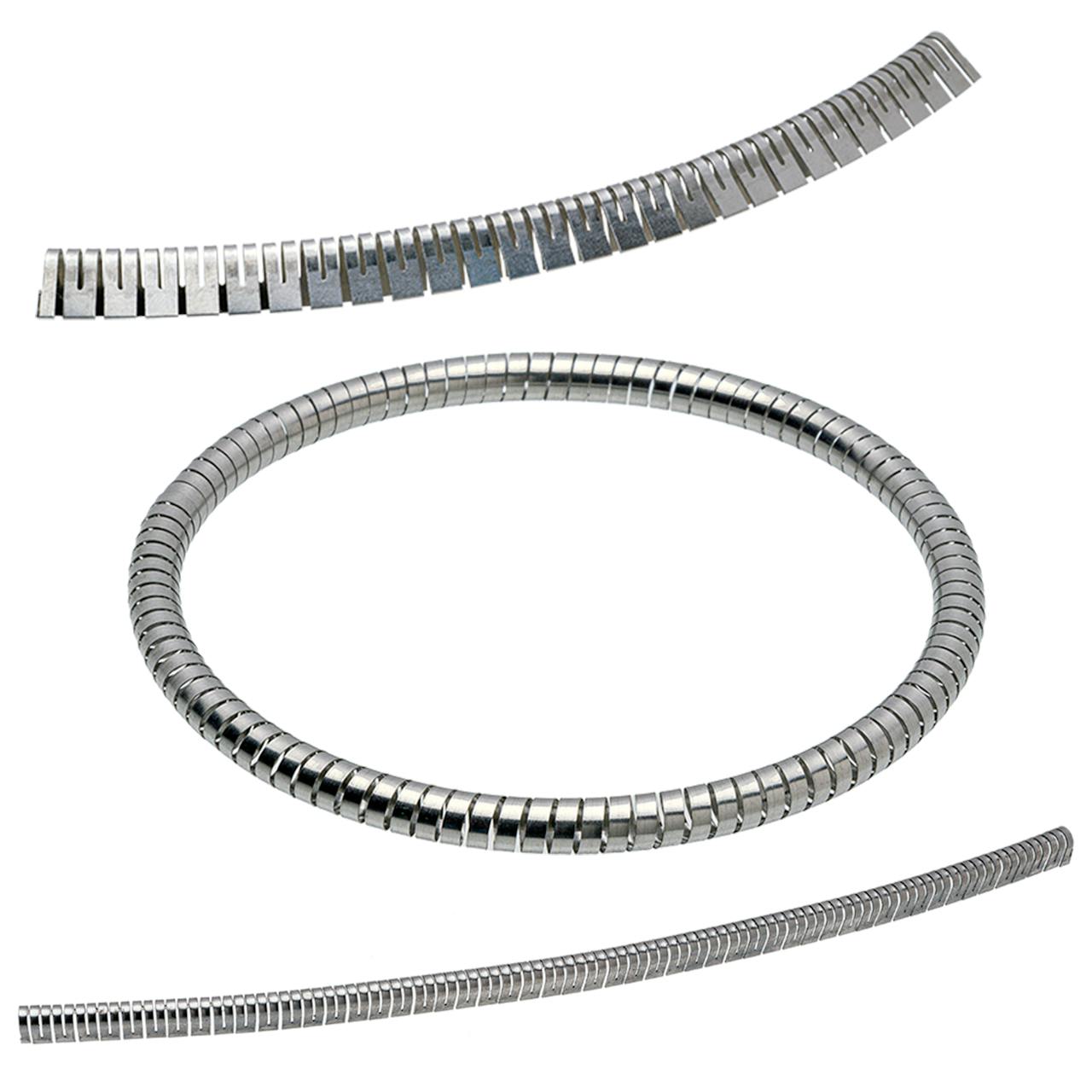

Spring Energizer Products

Maudlin's spring energizer products help overcome the load limitations of polymer seal jackets, including pressure, temperature, and the tolerances of surrounding components. They provide more consistent performance and can include V-springs, U-springs, helical springs, full contact springs, slant coil springs, and Q-connect slant coil springs.

Check out our spring energizer products, configurations, and performance data.

-

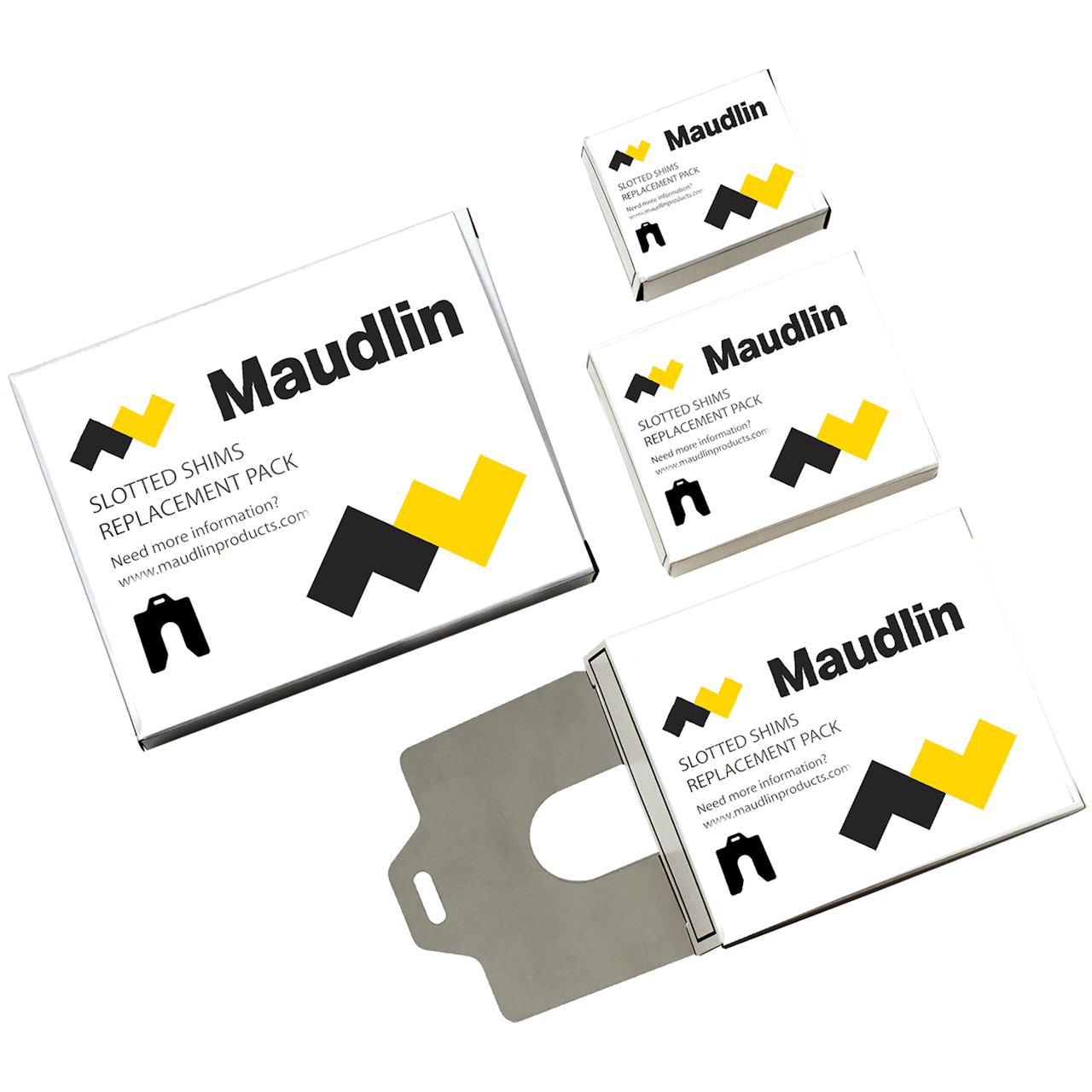

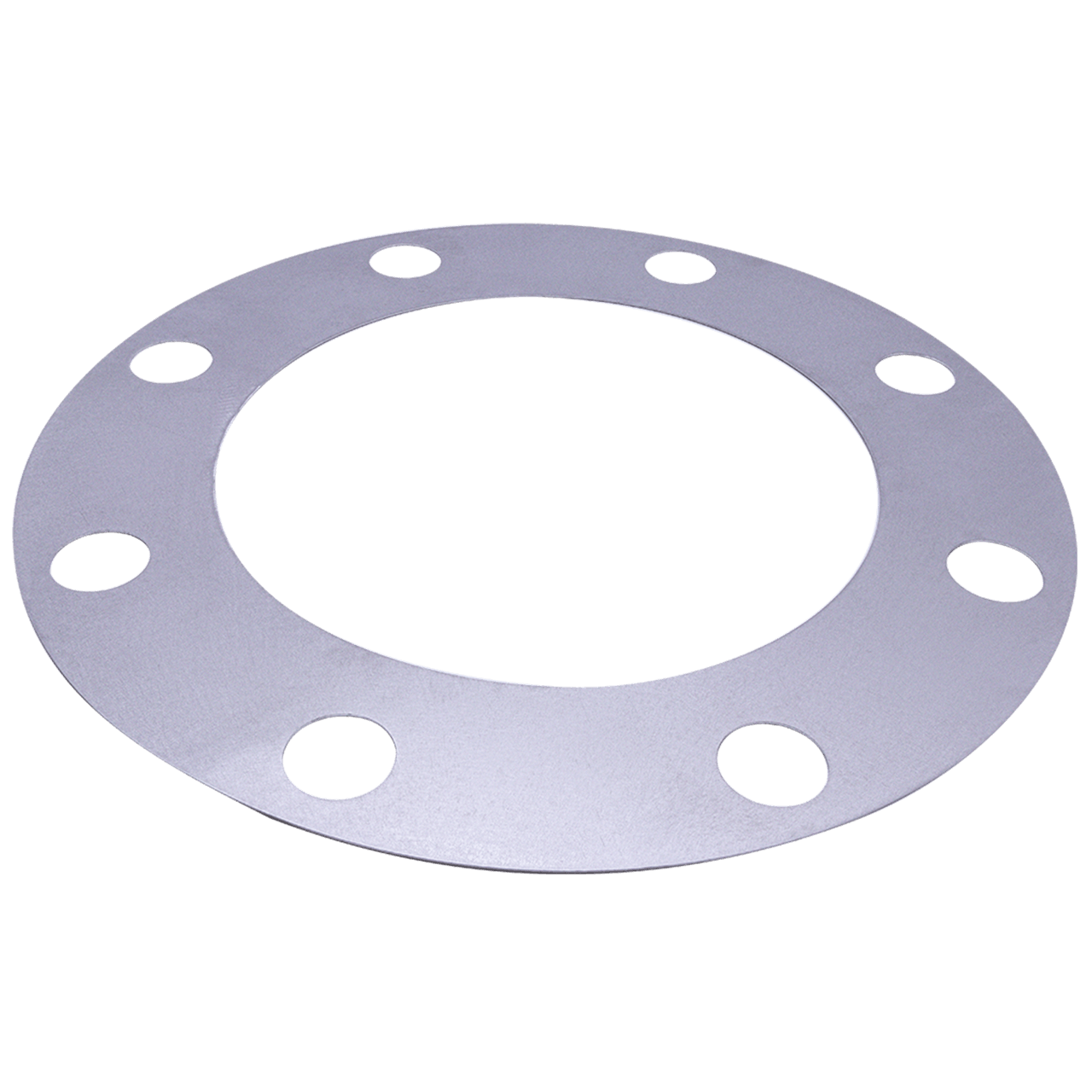

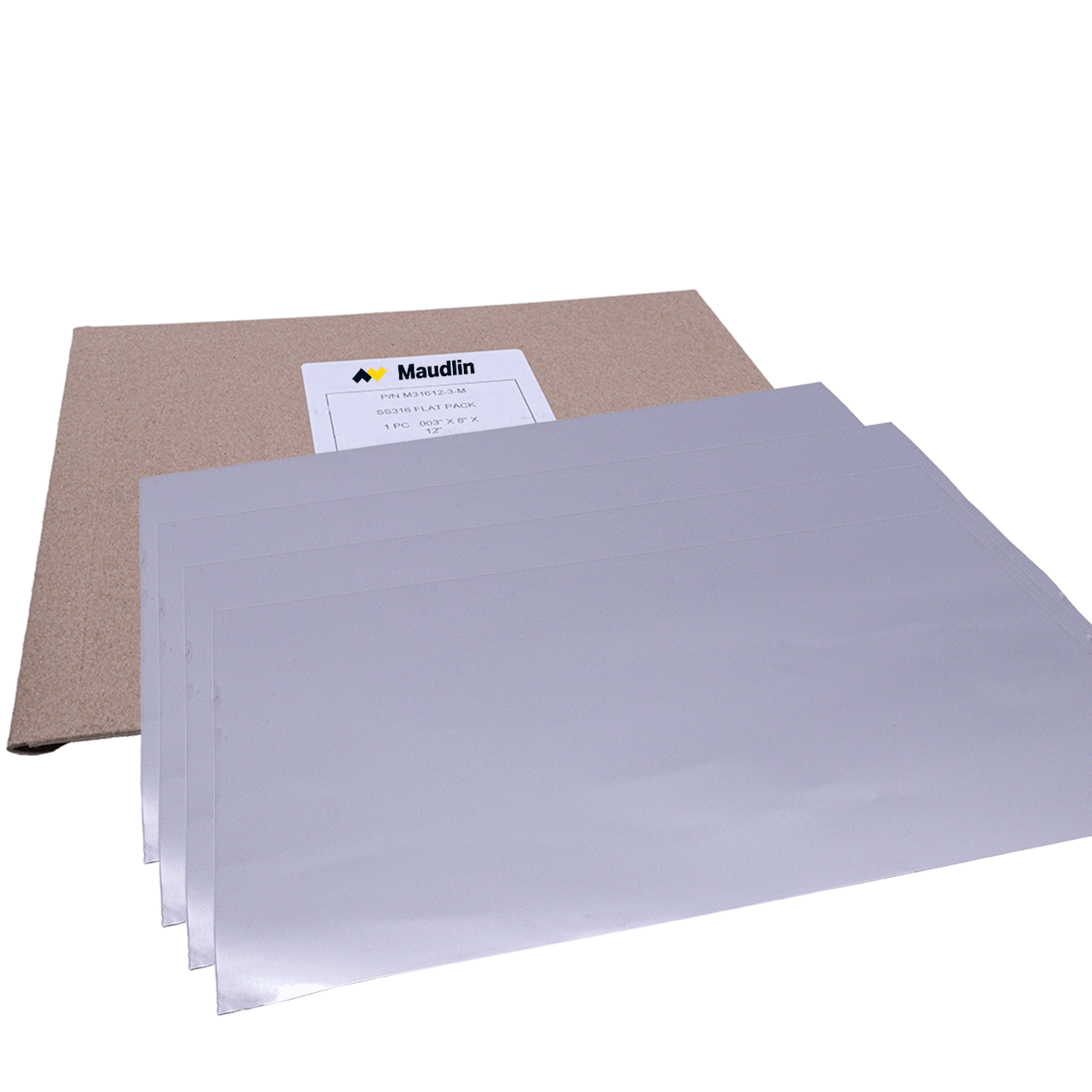

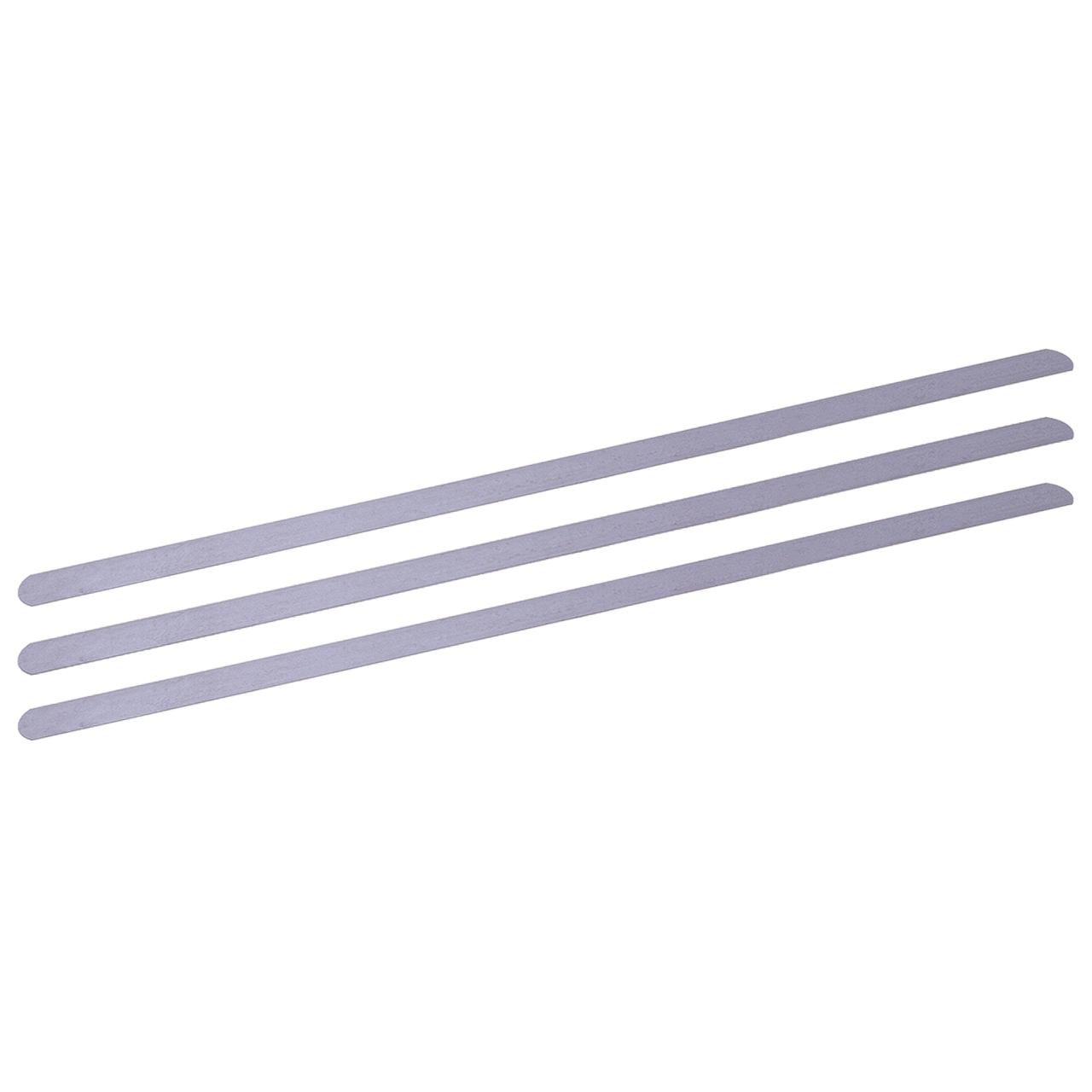

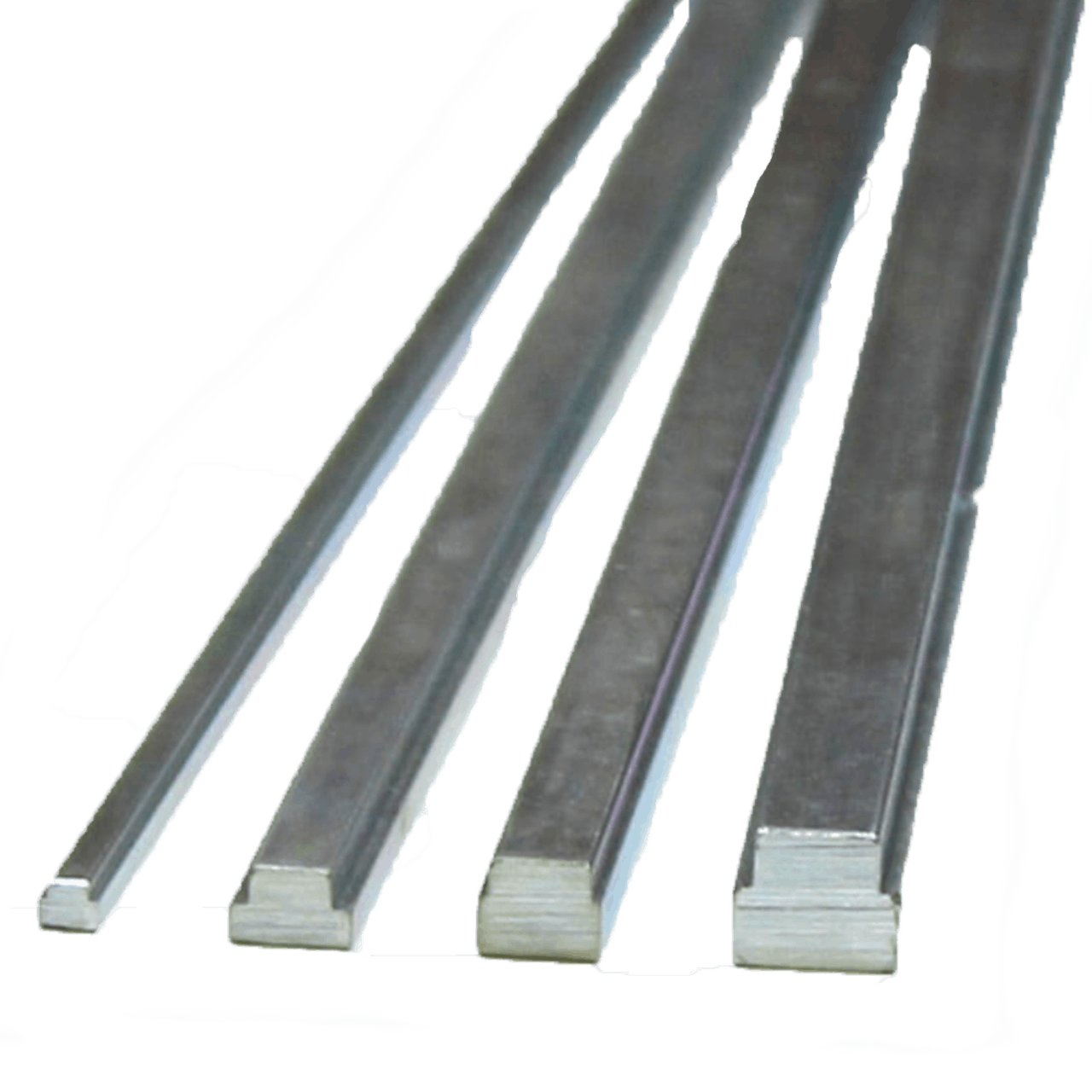

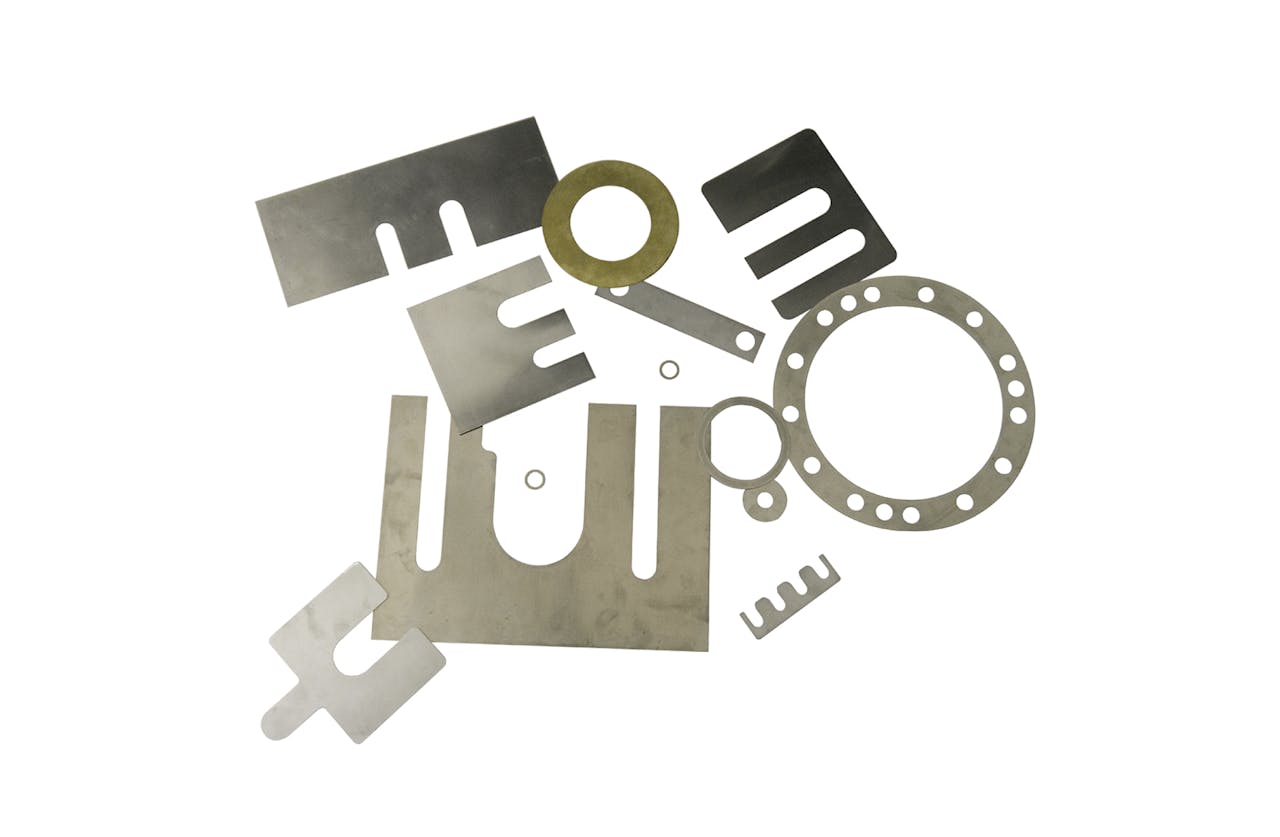

Shims

Shims help align your equipment to reduce damaging vibrations. The right shims can greatly reduce mechanical breakdowns and the frequency and expense of repairs. Maudlin offers a variety of metal and plastic shims manufactured to both standard and custom specs with some of the fastest turnaround times in the industry.

Check out our shim products, shop stock or standard shims, or request a quote for custom shims.

Download the Maudlin Catalog

Browse our catalog for more information on our spring energizer and shim products. In the catalog, you’ll find details on our products, including specifications, available materials, and more. Download the online catalog now or contact us to request a print copy.

24-Hour Turnaround Time on Stock Items

Maudlin manufactures only the highest quality stock and custom parts – and we do it fast. We offer 24-hour turnaround time on all stock items and our experienced personnel will do everything in their power to ensure your rotating equipment needs are met.

In an environment where speed and thousandths of an inch matter, you would accept nothing less than the best. Neither do we. Our commitment to craftsmanship, quality, and meeting the most demanding industrial requirements help you get the parts you need, right when you need them.

The Industry's Fastest Turnaround Time for Custom Shims

Maudlin offers quick turn service for custom shims, with most lead times under five days. From plastic shims to thick steel foundation shims that are designed to withstand extreme pressure, we can manufacture the custom shims you need to reduce damaging vibration and wear on your machines.

MADE TO ORDER SPRINGS FOR YOUR APPLICATION

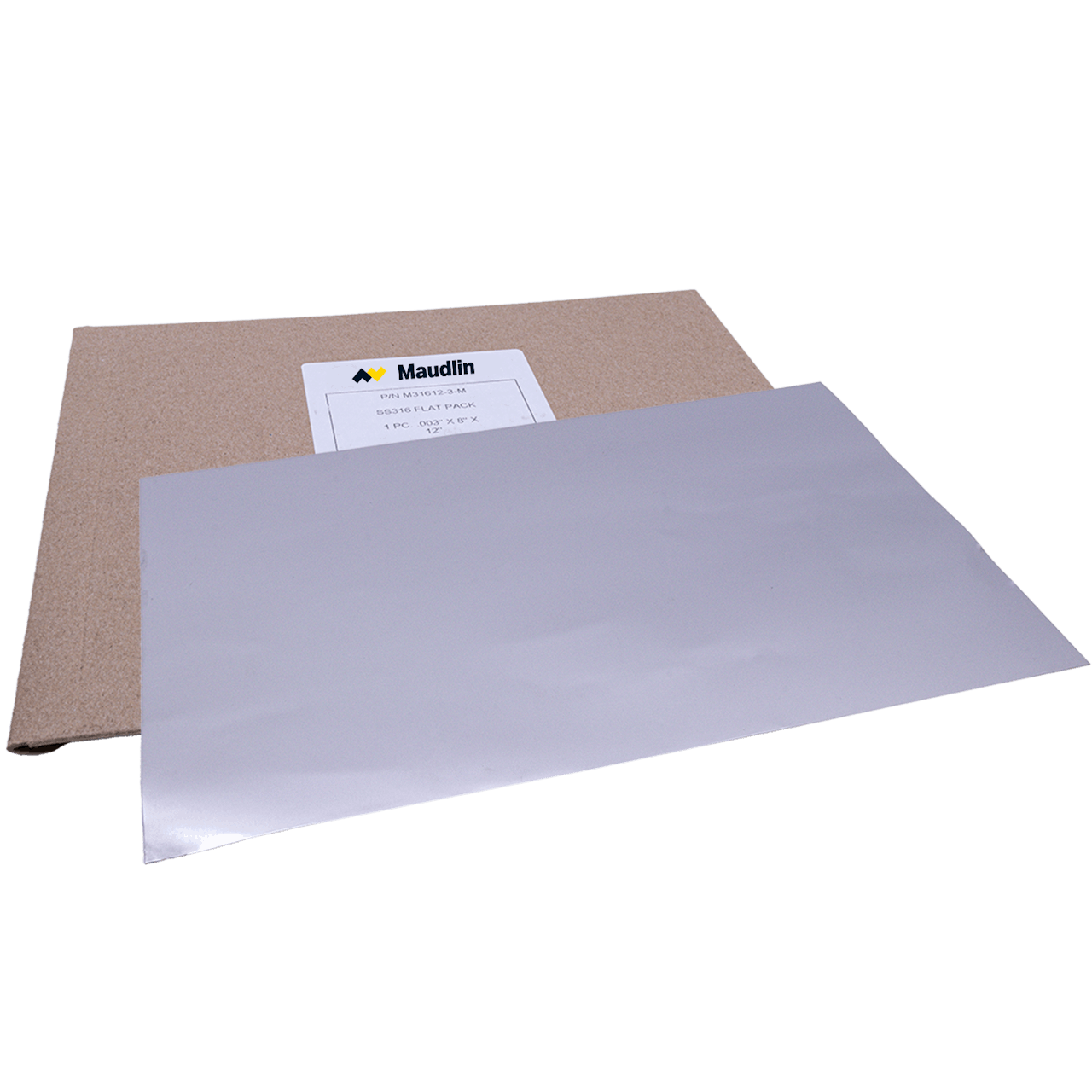

Custom Spring Energizers

Not finding what you need in a standard spring? Maudlin offers custom energized spring manufacturing. All our custom springs are made to order and can be manufactured in Elgiloy, SS301, SS304, SS316, Hastelloy, or Inconel. Full prints are available upon request. Get in touch with us today to discuss how we can customize a spring for your application.