Spring Energizers - Welded Vs. Non-Welded

Are you looking for features and benefits of welded spring energizers vs. non-welded spring energizers? You've come to the right place. MW Components produces spring energizer products in various configurations, cut to fit your application in either welded or non-welded varieties.

Benefits of Welding Spring Energizers

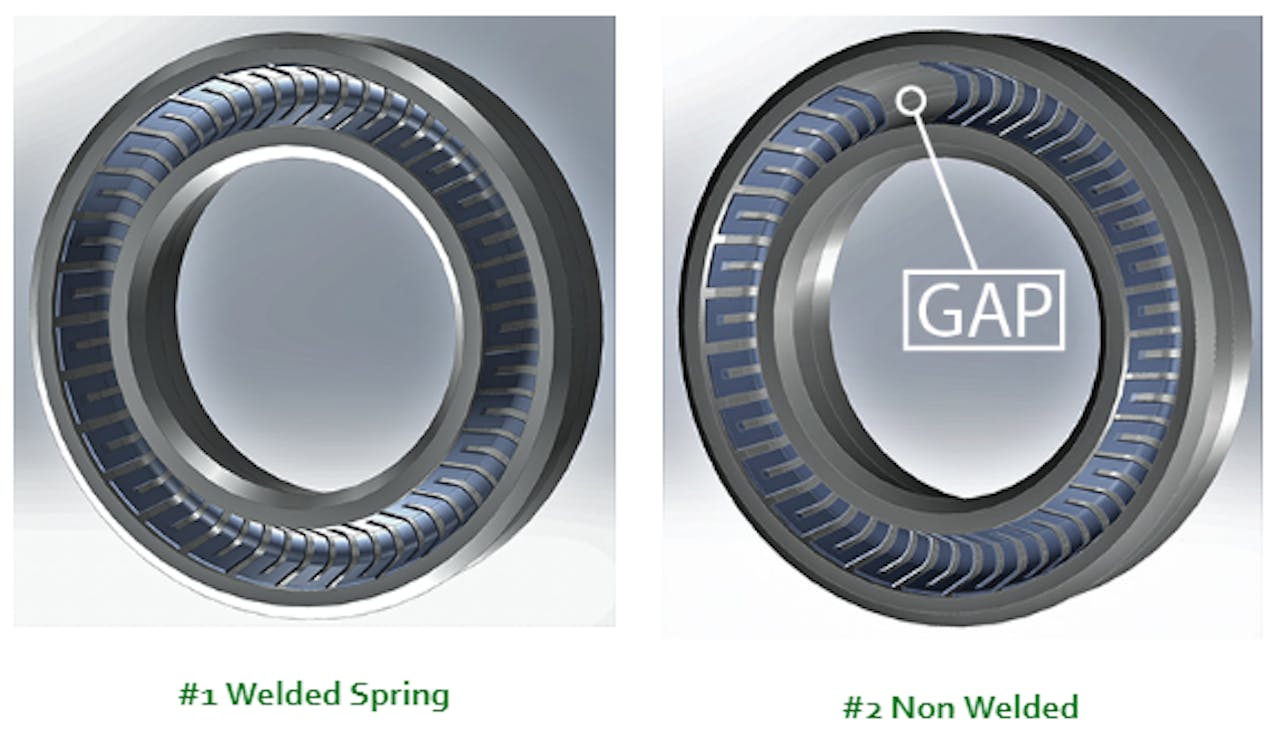

The purpose of the spring in a spring energized seal is to create a positive seal in the absence of system pressure. Unlike garter springs that pull in one direction, Cantilever, Slant Coil, and Helical springs are designed to apply force in two directions. This is why the correct spring centerline and a strong weld are critical. To the seal, the spring should look continuous without any breaks or voids along either contact surface. When there is a gap in the spring, a leak path is created and the seal will perform inconsistently if not fail altogether. The illustrations below show the difference between a good, continuous spring versus a non-welded spring with gaps.

Welding Spring Energizers Vs. Non-Welded Spring Energizers

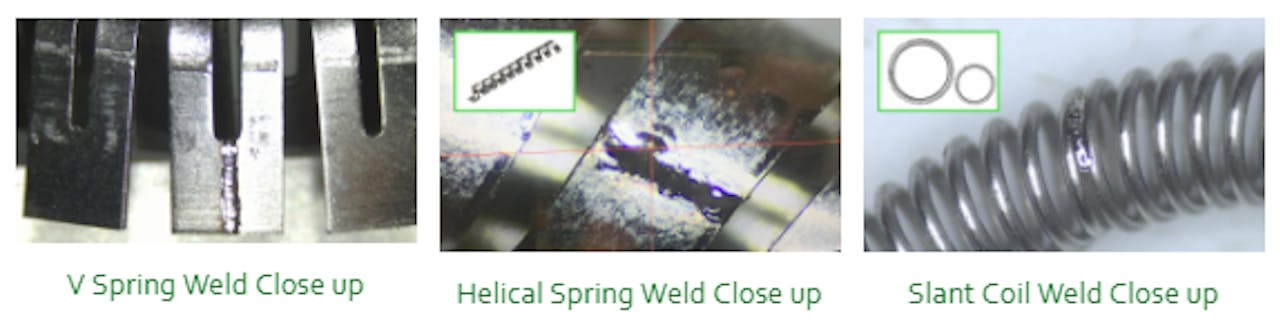

The gap shown in illustration #2 is due to the spring not being welded allowing the spring to separate inside the seal jacket. For this reason, MW offers pre-cut and welded springs to fit your specific application. Just tell us the desired spring type and the centerline of your spring groove and we can cut and weld a spring that fits perfectly and gives the continuous, circumferential load necessary for positive sealing. Consult our factory with any questions regarding cut length, centerline, and weld type. Regarding the weld itself; At MW Components, we use only the latest in laser welding technology. Laser welding allows for precise spring diameters and strong, continuous welds without the overlaps or tabs required for spot welding. The pictures below show three types of springs that have been laser welded.

Ask an Expert

Have questions about spring energizer products, including cut length, configurations, or welding styles? Contact an MW expert, for more details.