Products > Spring Energizer Products

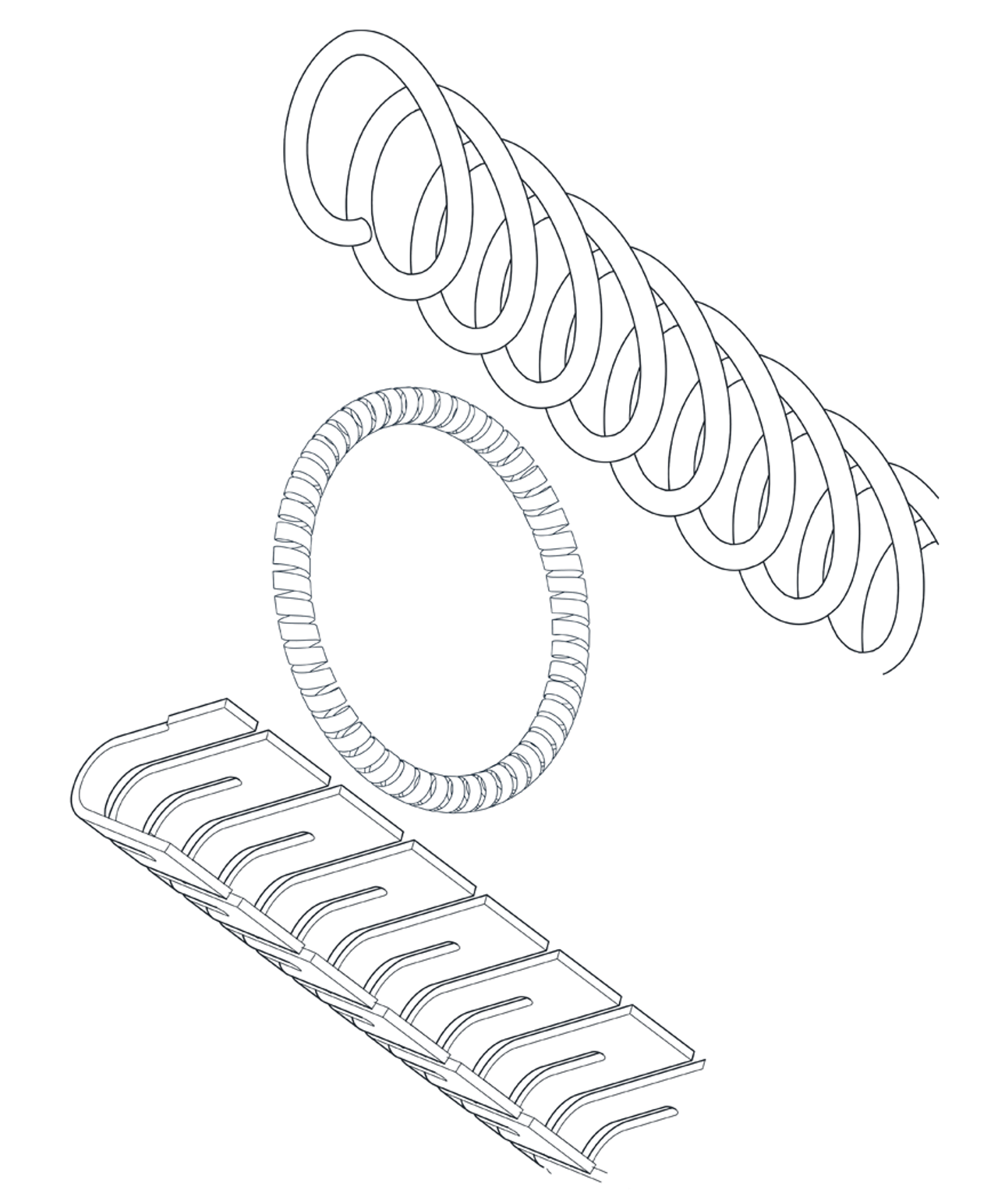

V Springs / Cantilever Springs

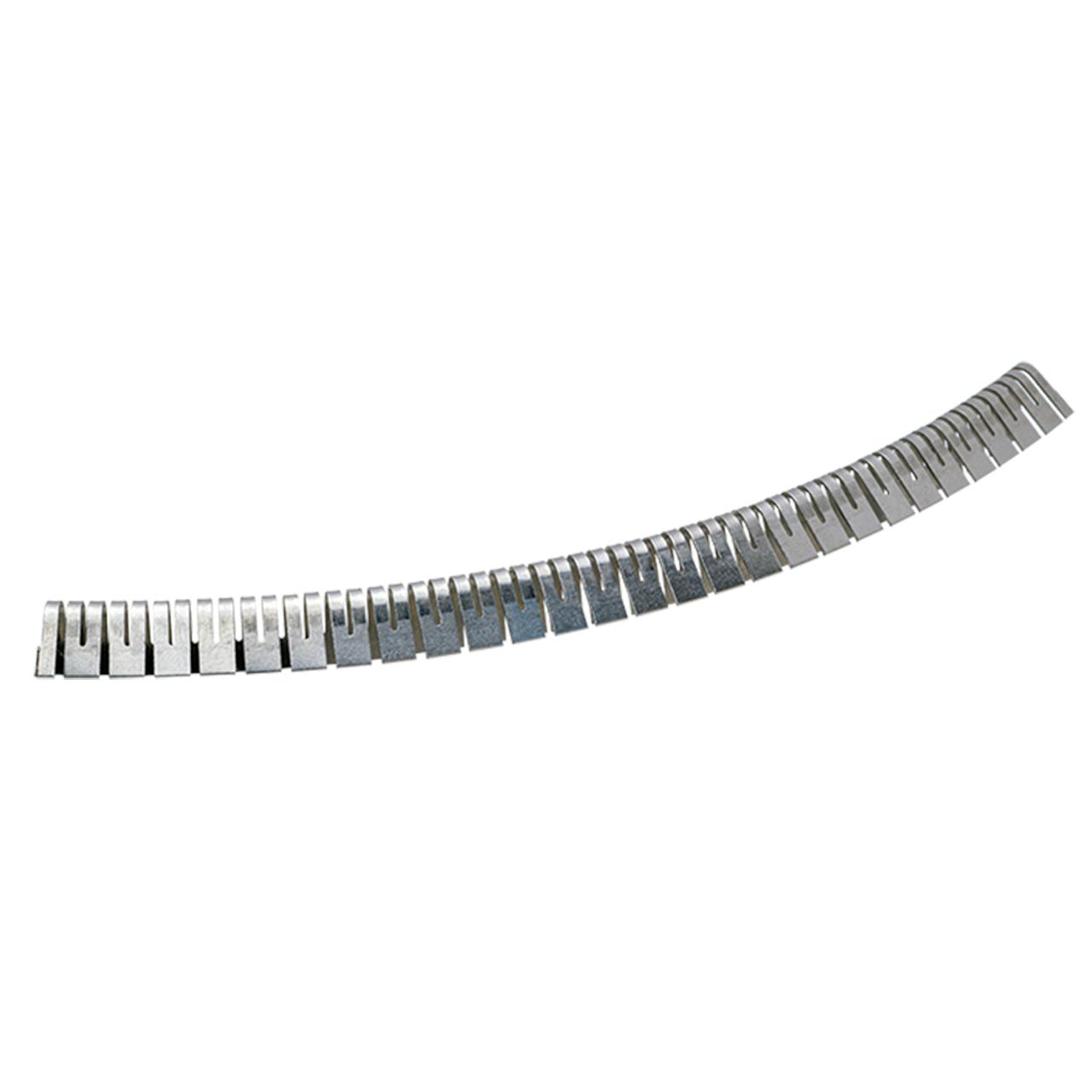

V springs, also referred to as cantilever springs, Meander V springs, or punch finger springs have a V-shaped pattern that allows them to provide an even linear load over a wide deflection range and can be used in both static and slow to moderate dynamic motion applications. Our Cantilever V-springs are created in continuous lengths from 100 ft. to annual quantities exceeding 100,000 ft. We produce V-spring energizers in either Elgiloy® or Stainless Steel.

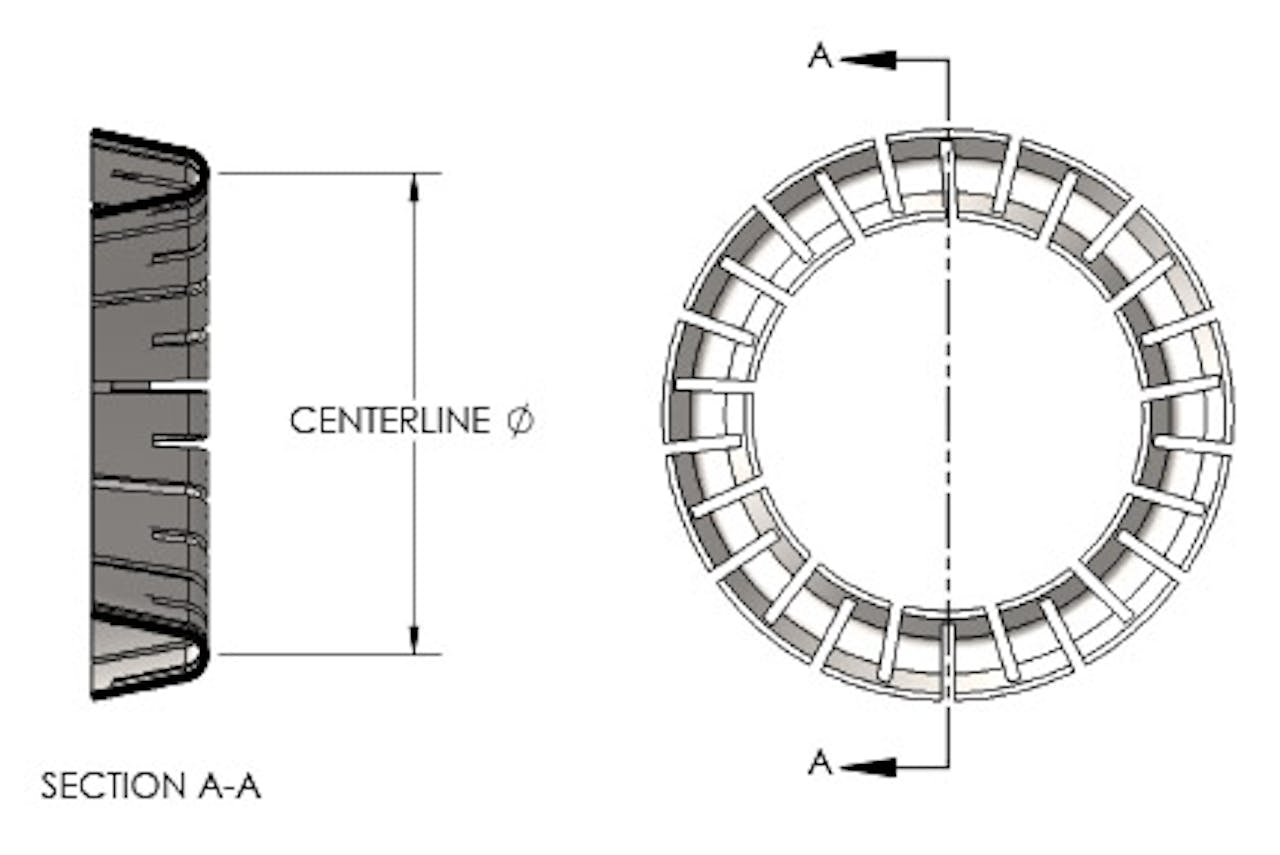

If you need pre-cut and welded V springs, we can produce these as well. Just reference our centerline diagram below to provide us the centerline measurement you need and we'll cut and weld the spring to the size required.

MANUFACTURED SPRINGS

Looking for Pre-Cut and Welded V Springs?

MW produces cut and welded springs for all standard industrial and metric dash sizes for 000 - 400 series spring energizers, including V-spring, Helical, and slant coil springs. Simply provide the dash number you need and we'll cut and weld the spring to the necessary dimensions.

Even if the product you need doesn't fall into the standard dash number range, we still have you covered. Provide the centerline of the spring groove in the seal and we will cut and weld a spring energizer to exactly match the dimensions. Our engineering and manufacturing experts are here to make fabrication and assembly as seamless as possible.

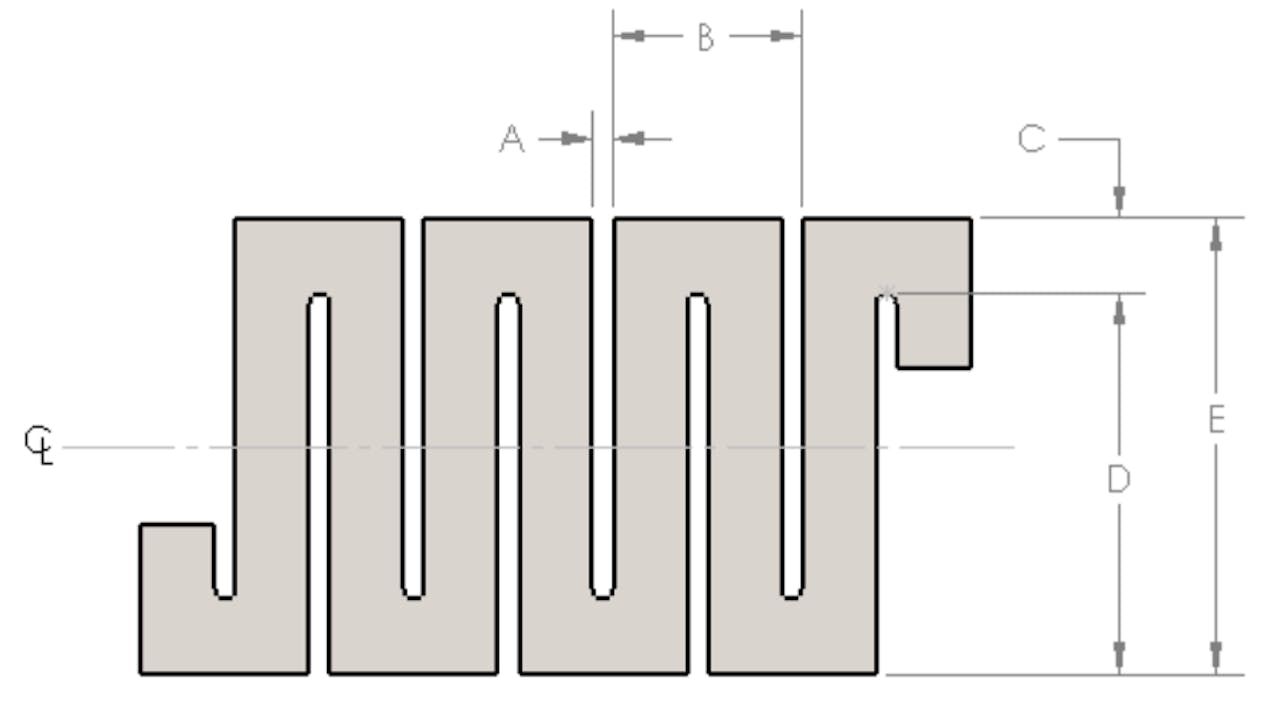

V Spring / Cantilever Spring Dimensional Data

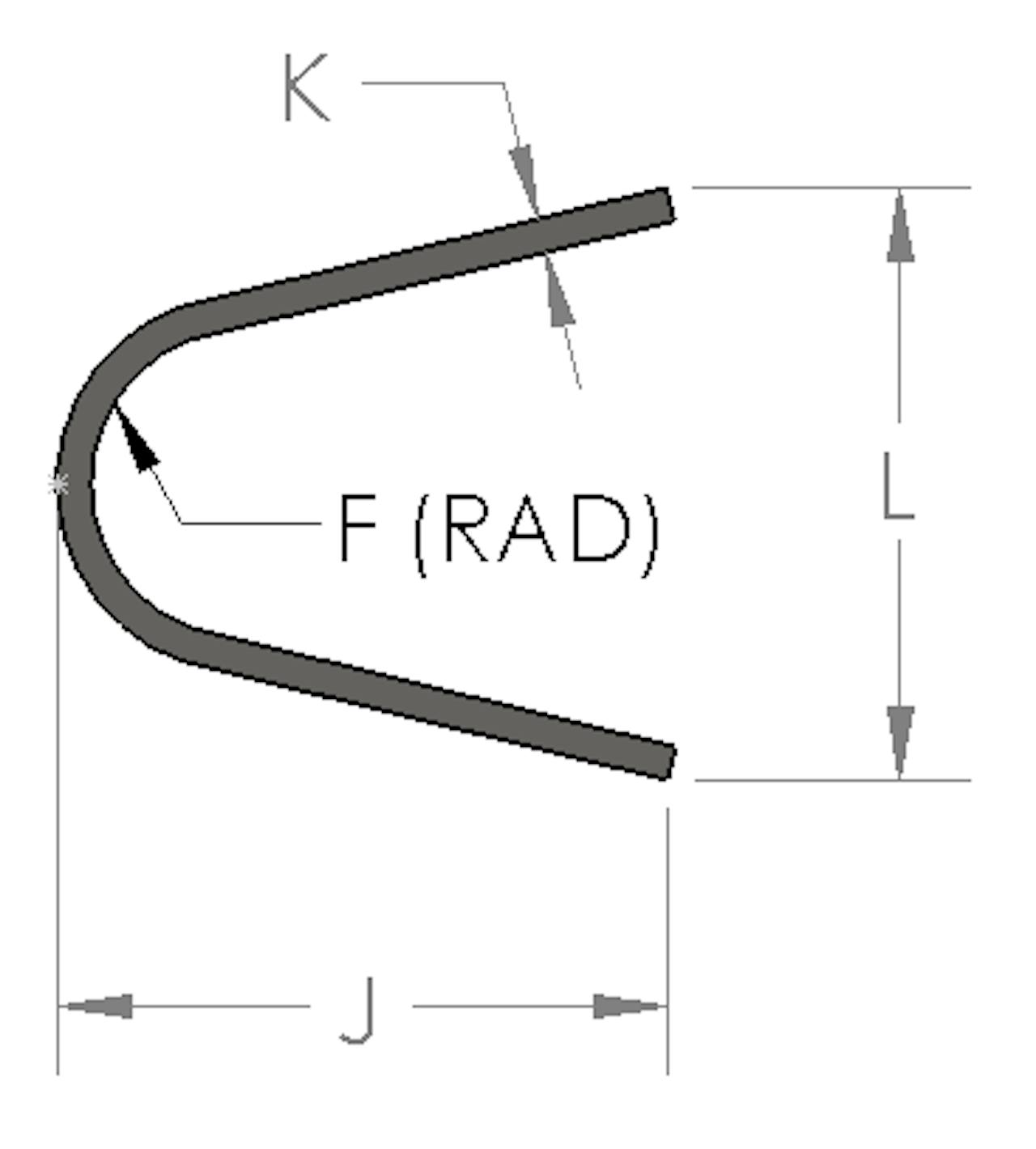

The chart below shows the standard dimensions for our Standard Cantilever V-Spring. All dimensions are subject to standard manufacturing tolerances. Those tolerances may be requested if needed. Each Cantilever V-Spring is manufactured in its own standard tool & die set. If these dimensions do not work for your situation, minor variations to the “L“ and “K” dimensions can be made with minor adjustments to our tooling. However, if you are in need of a more aggressive change (such as the width of the raw material or radius dimensions) we suggest you inquire about one of our 100 or more nonstandard cross-sections of spring.

*If you still can’t find the geometry you like, a unique toolset can be designed specifically for your application. Ask an MW expert for details.

Standard Dimensions

Dimensions A-F

| Series | A | B | C | D | E | F | J | K | L |

|---|---|---|---|---|---|---|---|---|---|

| -000 | .016" | .067" | .020" | .080" | .101" | .010" | .041" | .003" | .047" |

| -100 | .010" | .080" | .030" | .146" | .176" | .014" | .080" | .005" | .071" |

| -200 | .011" | .100" | .040" | .202" | .242" | .029" | .105" | .006" | .101" |

| -300 | .020" | .150" | .055" | .335" | .390" | .049" | .160" | .008" | .173" |

| -400 | .025" | .200" | .075" | .477" | .552" | .065" | .235" | .010" | .245" |

| -500 | .035" | .200" | .150" | .650" | .800" | .070" | .360" | .020" | .318" |

Metric Dimensions

Dimensions J, K, L

| Series | A | B | C | D | E | F | J | K | L |

|---|---|---|---|---|---|---|---|---|---|

| -000 | 0.41 MM | 1.70 MM | 0.51 MM | 2.03 MM | 2.57 MM | 0.25 MM | 1.04 MM | 0.08 MM | 1.19 MM |

| -100 | 0.25 MM | 2.03 MM | 0.76 MM | 3.71 MM | 4.47 MM | 0.36 MM | 2.03 MM | 0.13 MM | 1.80 MM |

| -200 | 0.28 MM | 2.54 MM | 1.02 MM | 5.13 MM | 6.15 MM | 0.74 MM | 2.67 MM | 0.15 MM | 2.57 MM |

| -300 | 0.51 MM | 3.81 MM | 1.40 MM | 8.51 MM | 9.91 MM | 1.24 MM | 4.06 MM | 0.20 MM | 4.39 MM |

| -400 | 0.64 MM | 5.08 MM | 1.91 MM | 12.12 MM | 14.02 MM | 1.65 MM | 5.97 MM | 0.25 MM | 6.22 MM |

| -500 | 0.89 MM | 5.08 MM | 3.81 MM | 16.51 MM | 20.32 MM | 1.78 MM | 9.14 MM | 0.51 MM | 8.08 MM |

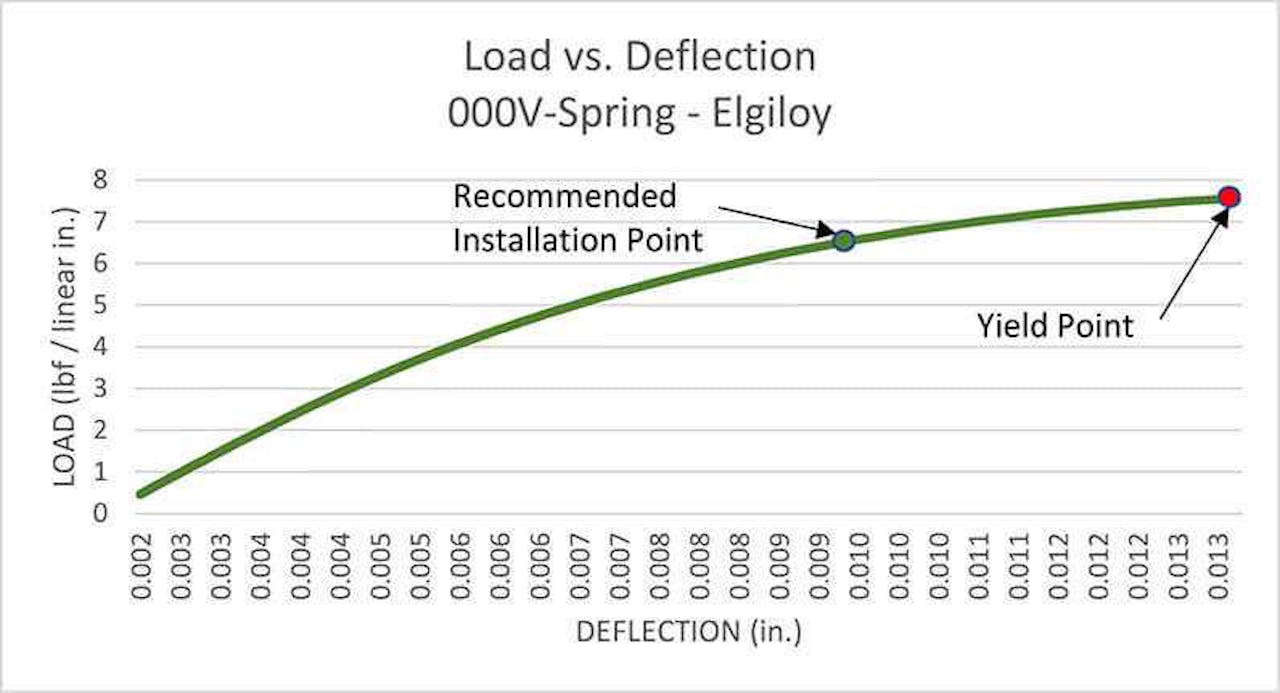

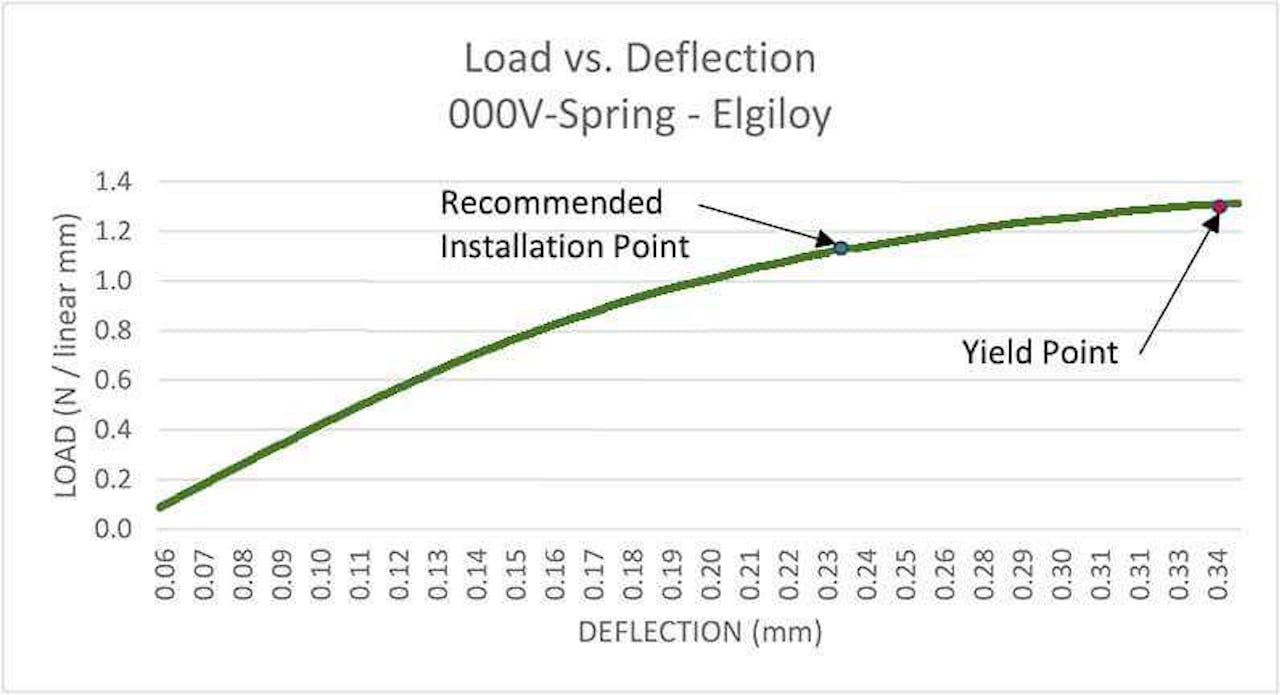

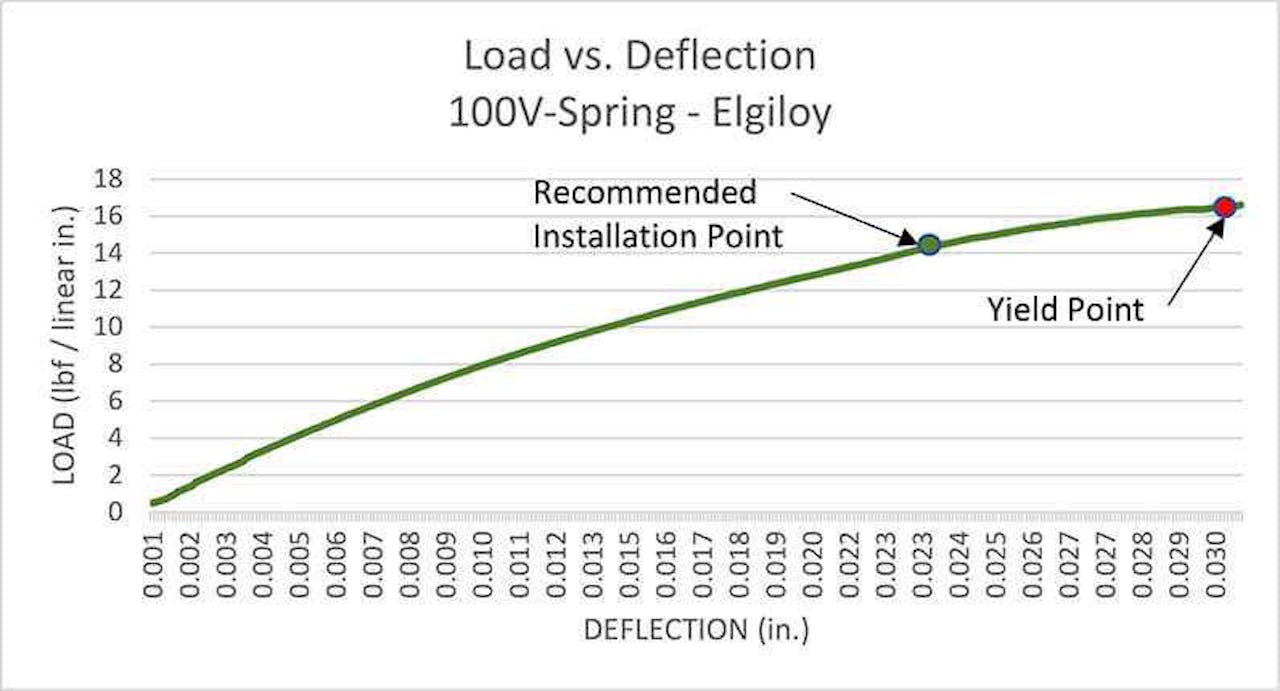

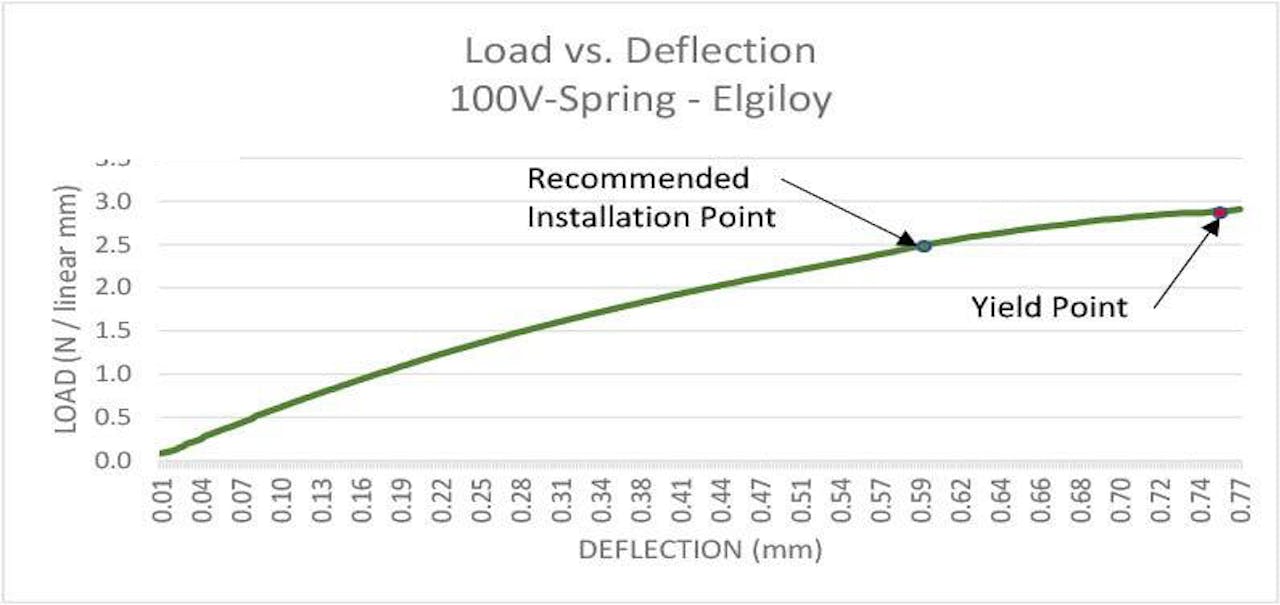

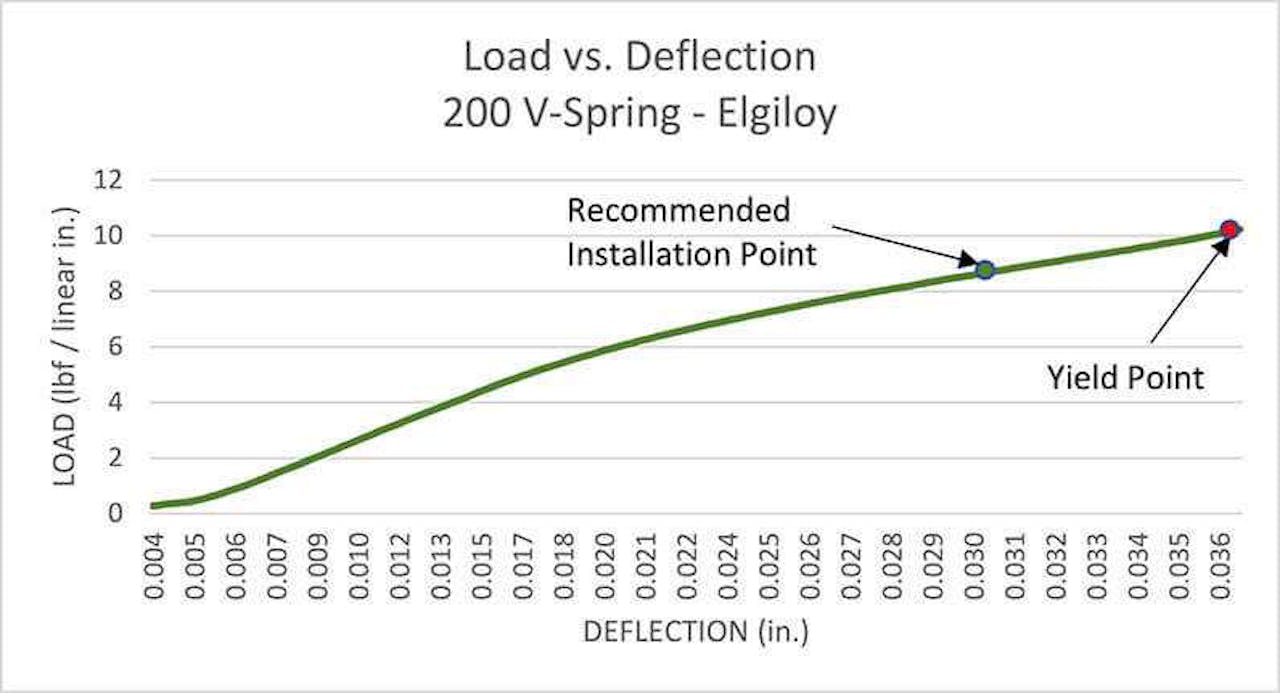

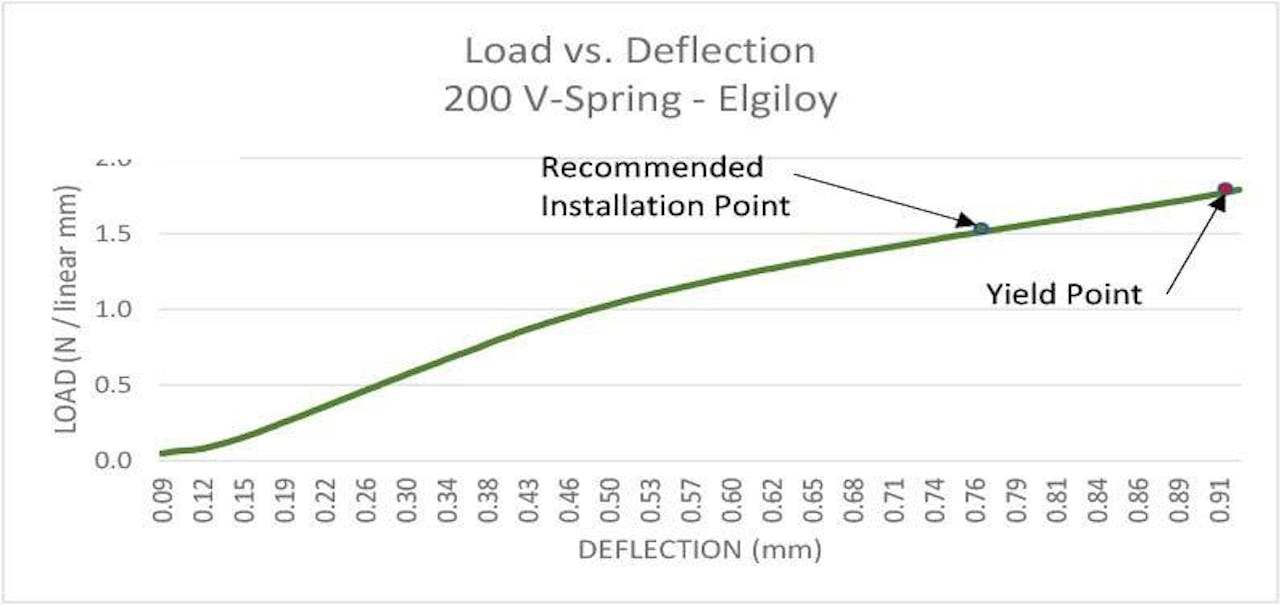

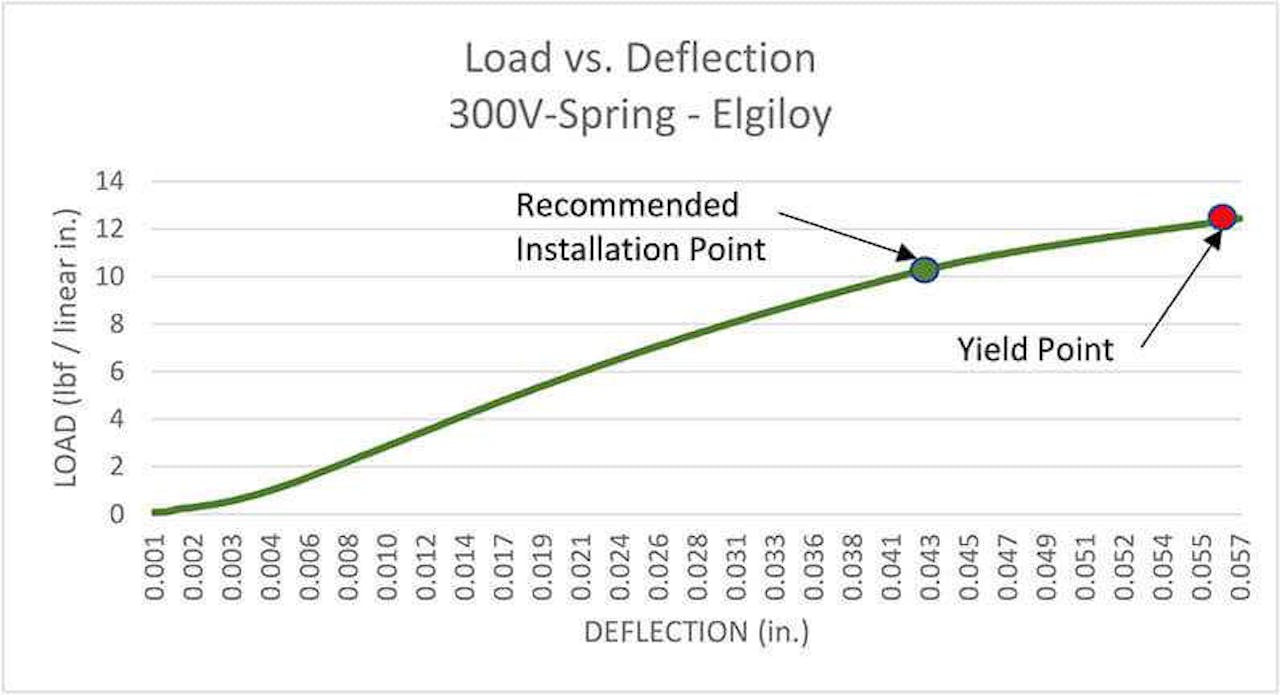

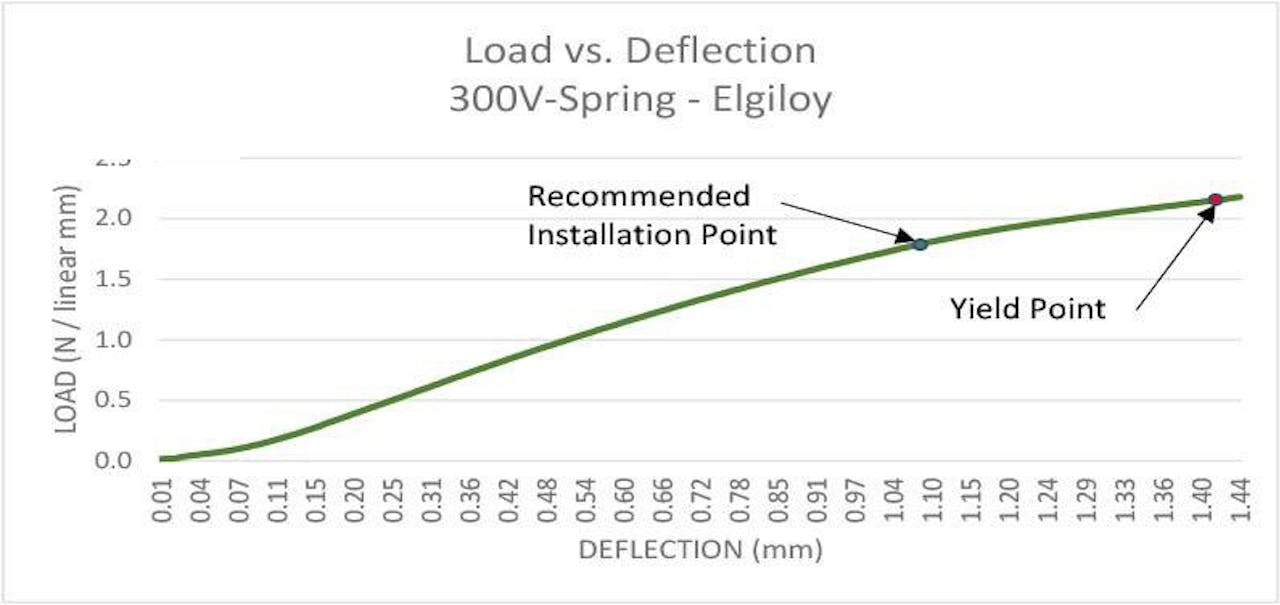

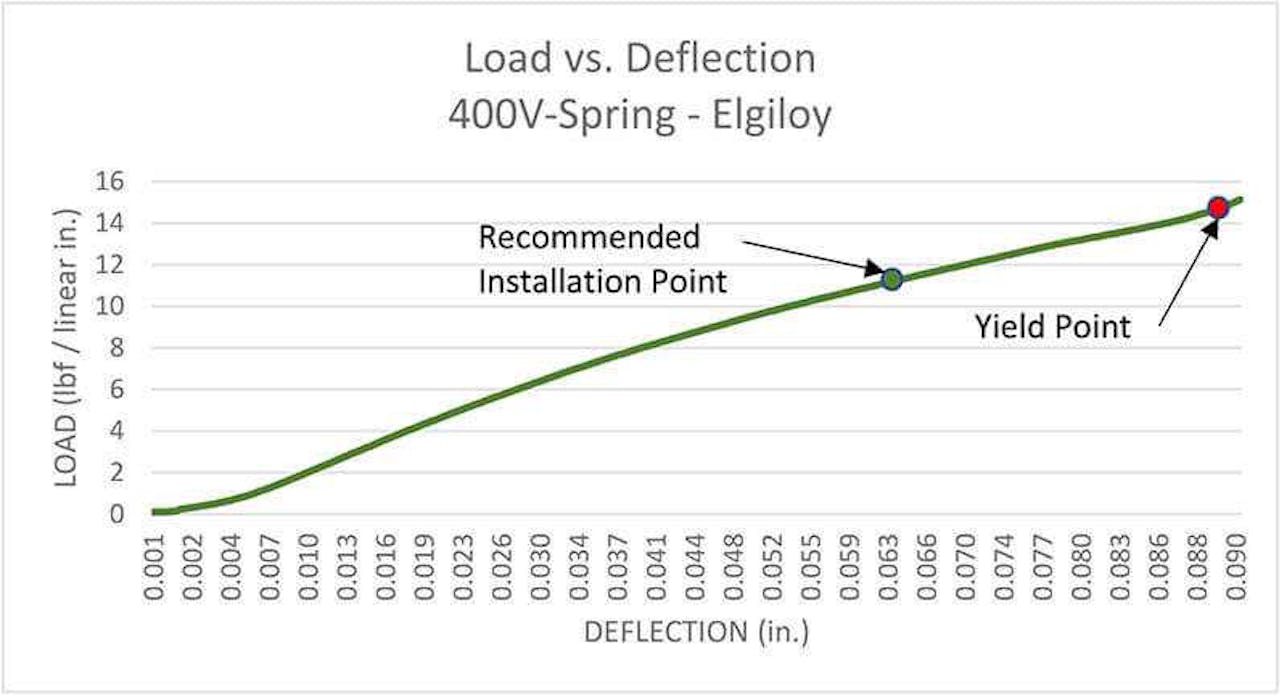

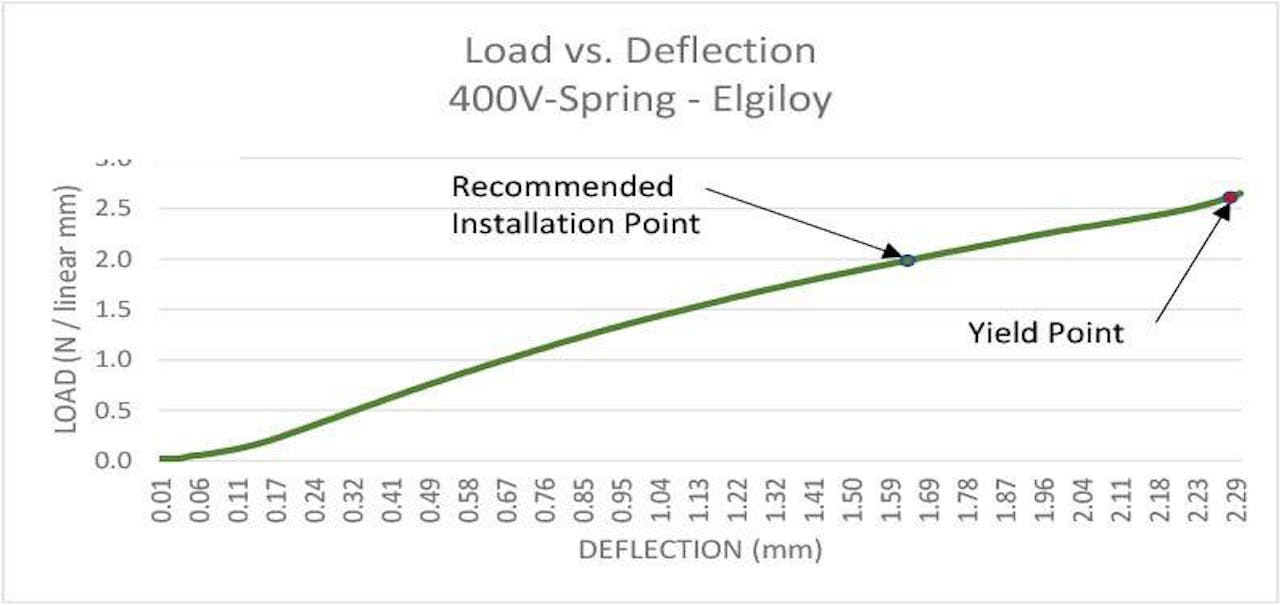

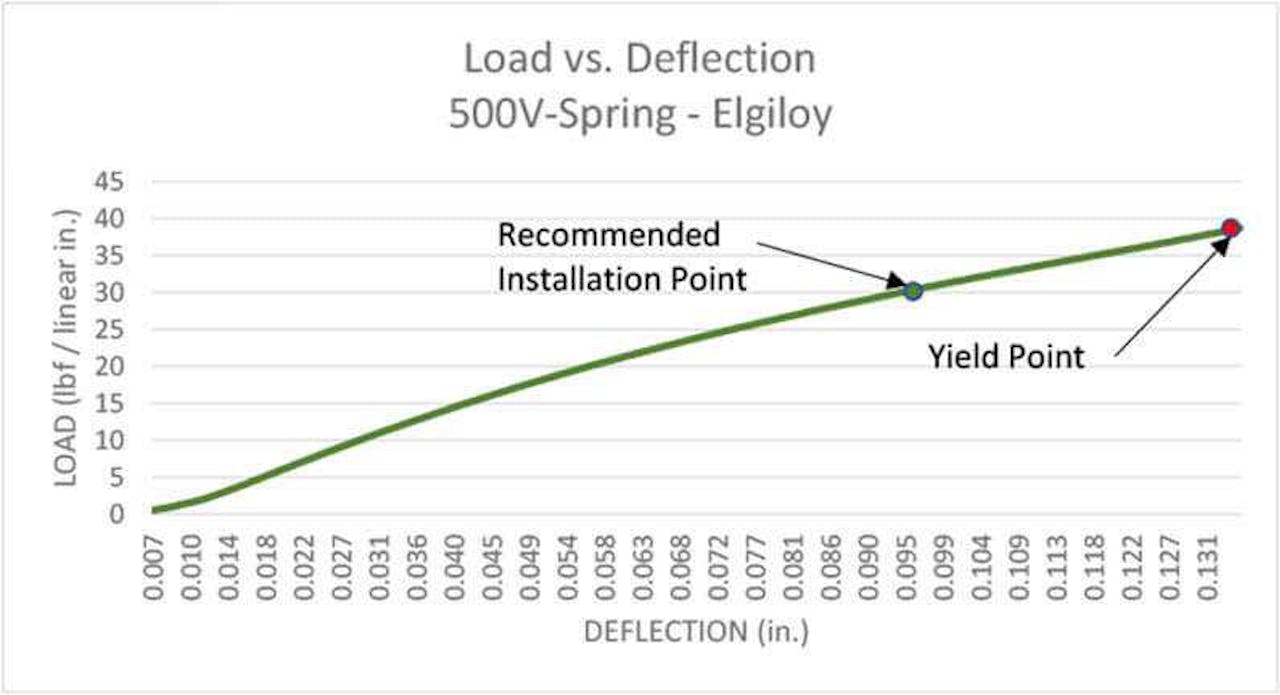

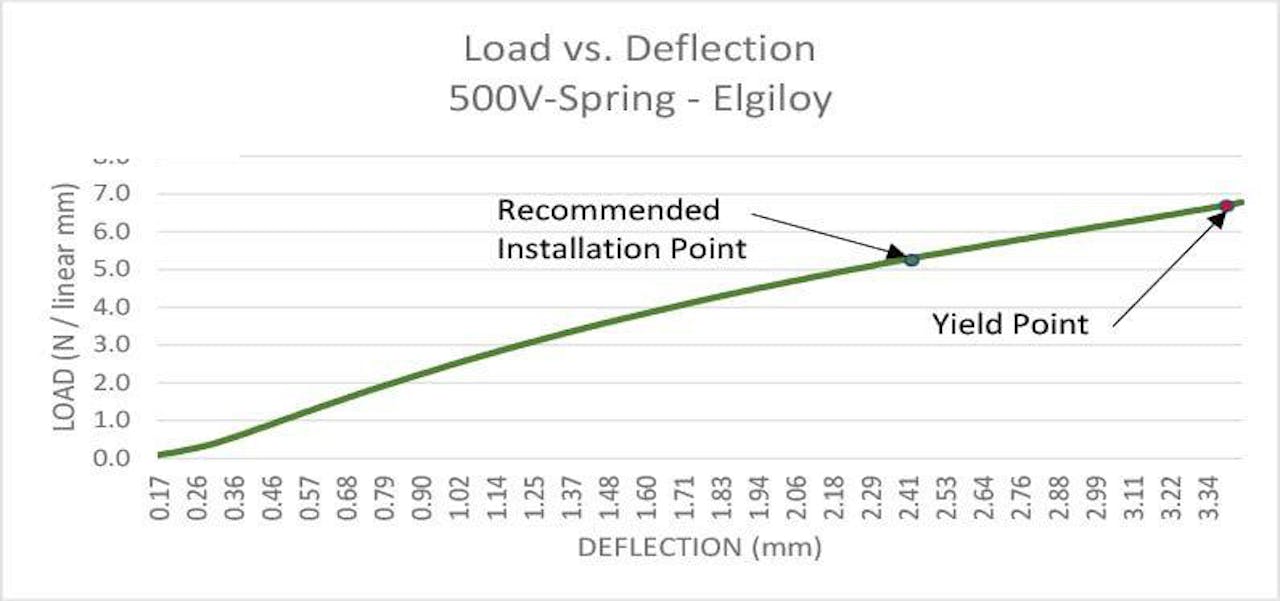

Elgiloy V Spring Load Deflection Testing

V-Spring-000-E-1

V-Spring-100-E-2

V-Spring-200-E-2

V-Spring-300-E-2

V-Spring-400-E-1

V-Spring-500-E-1

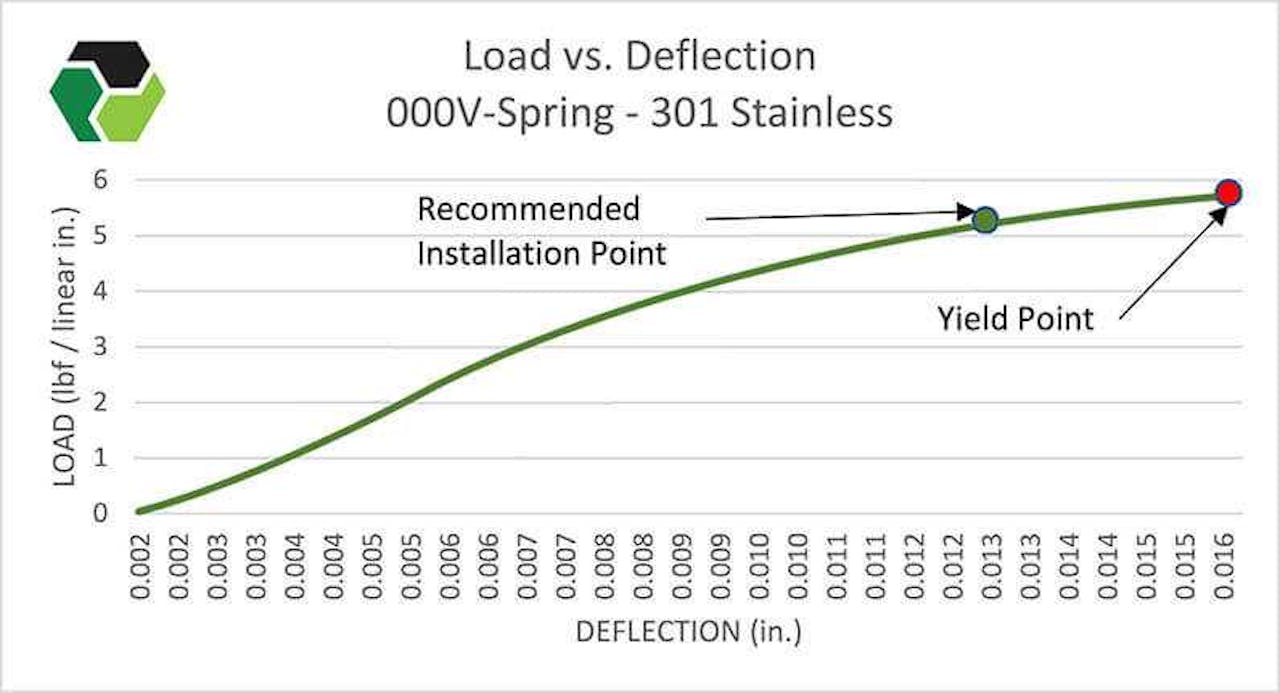

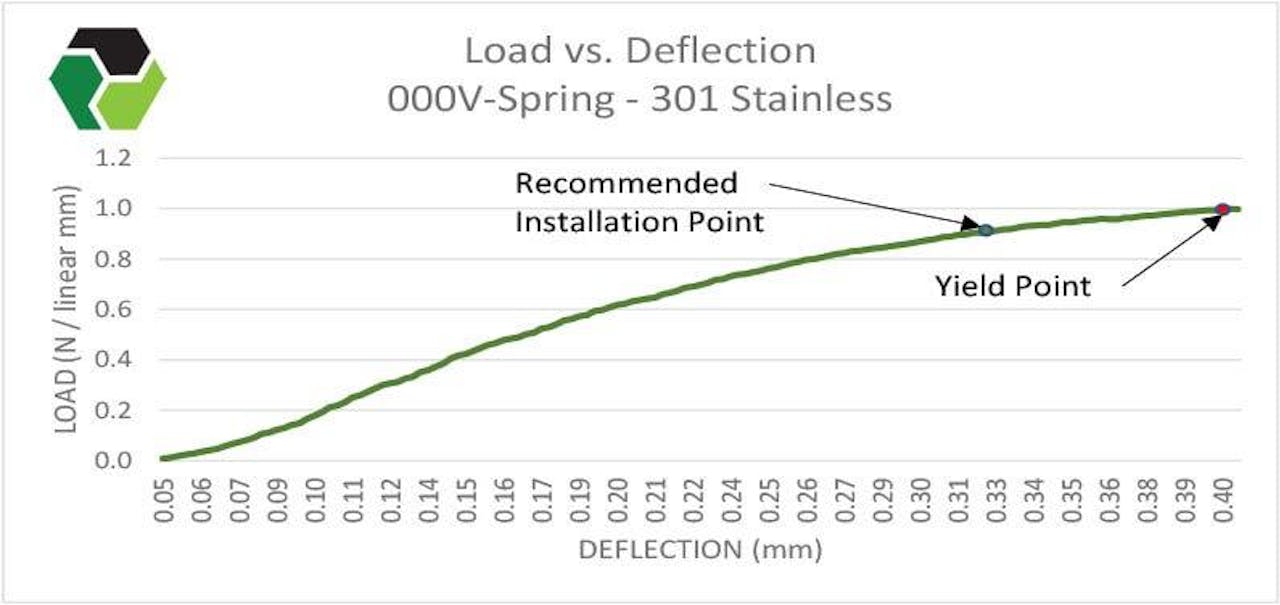

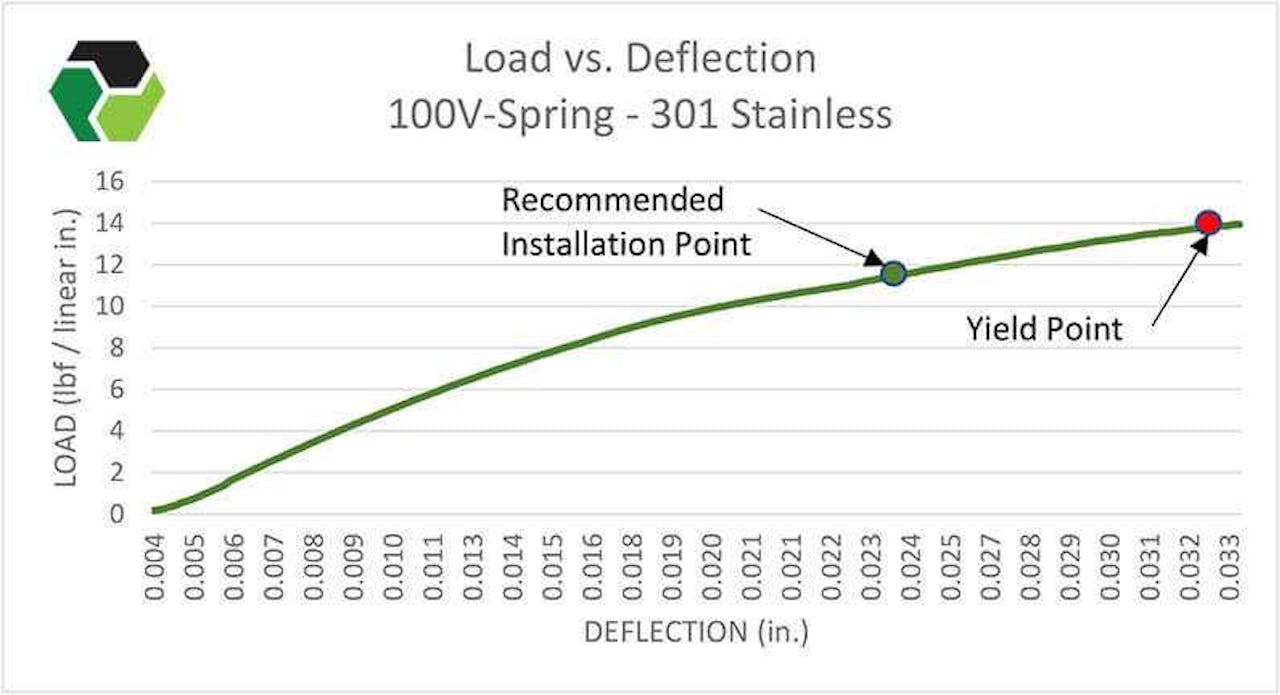

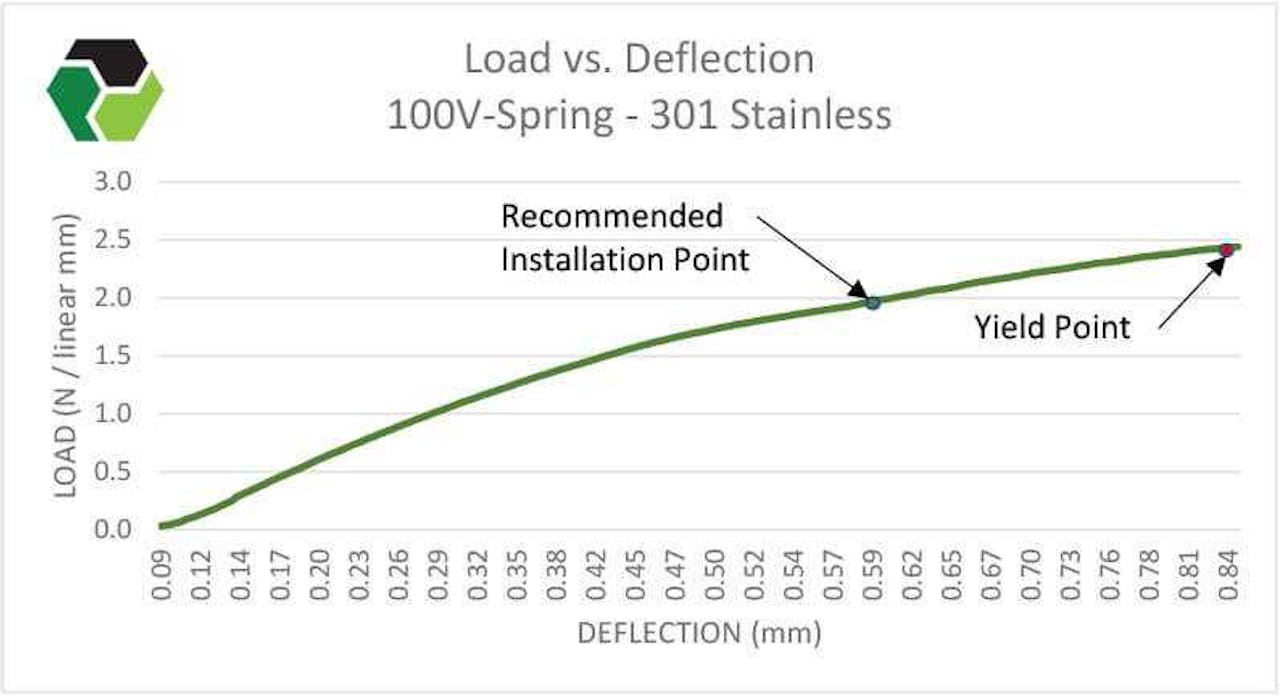

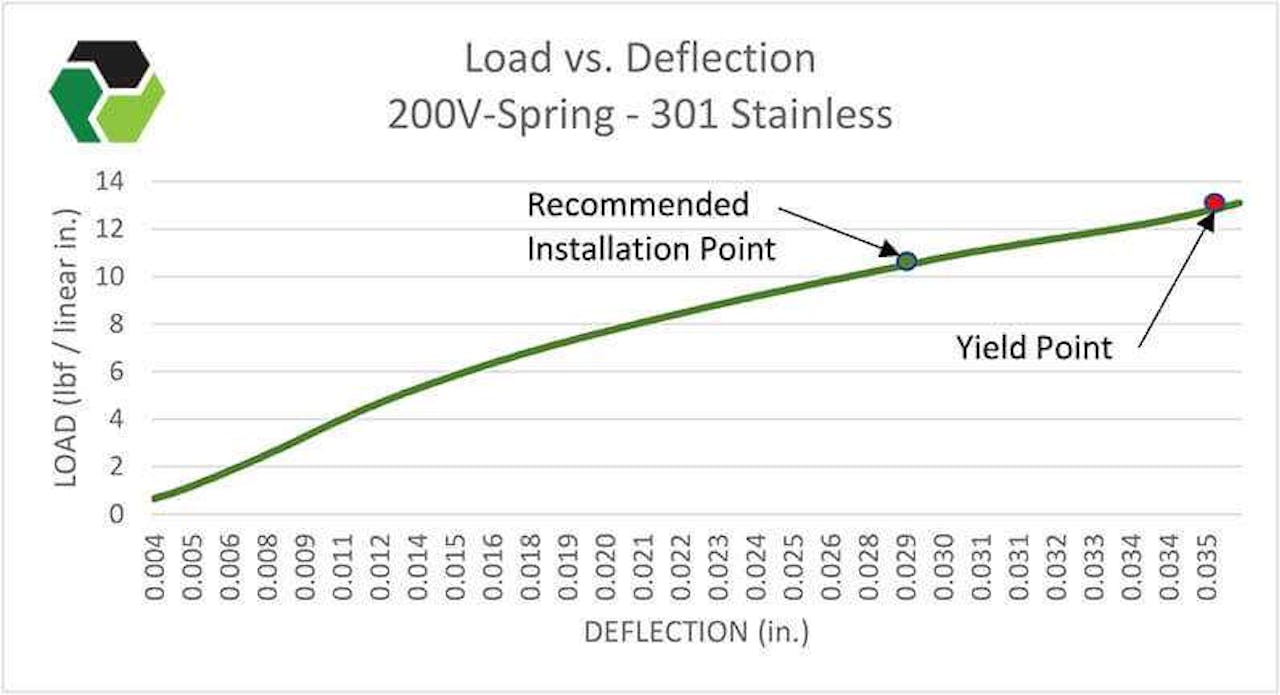

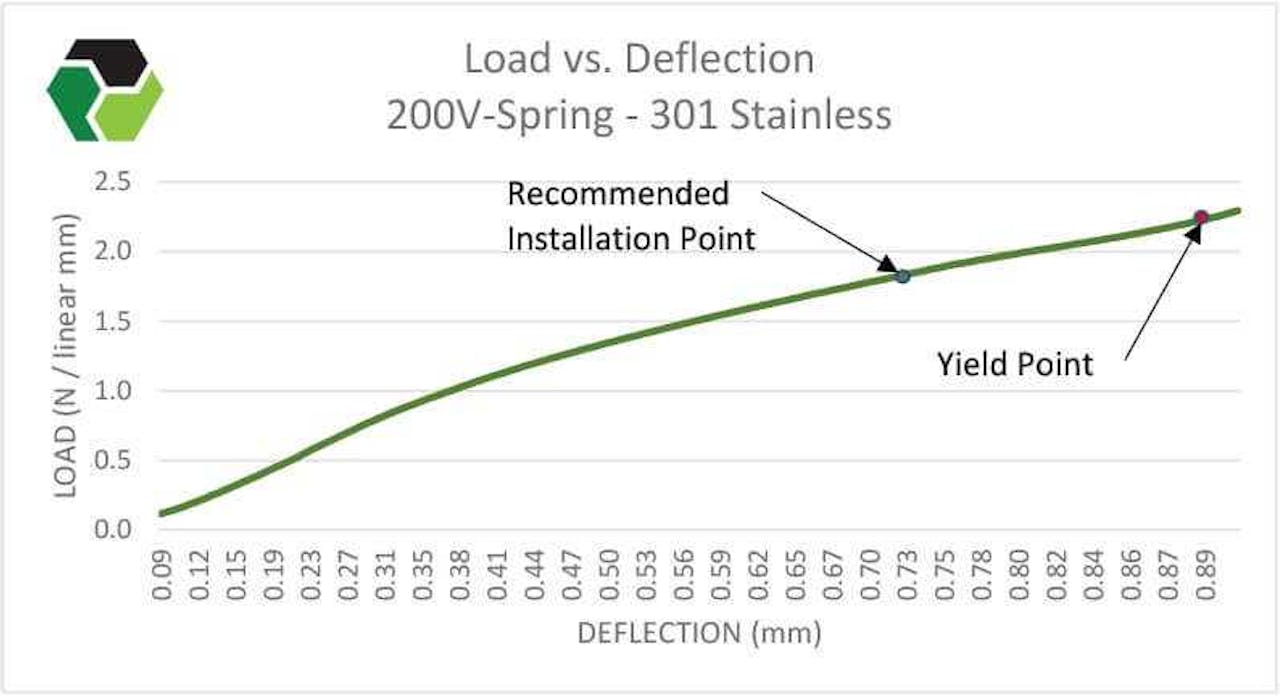

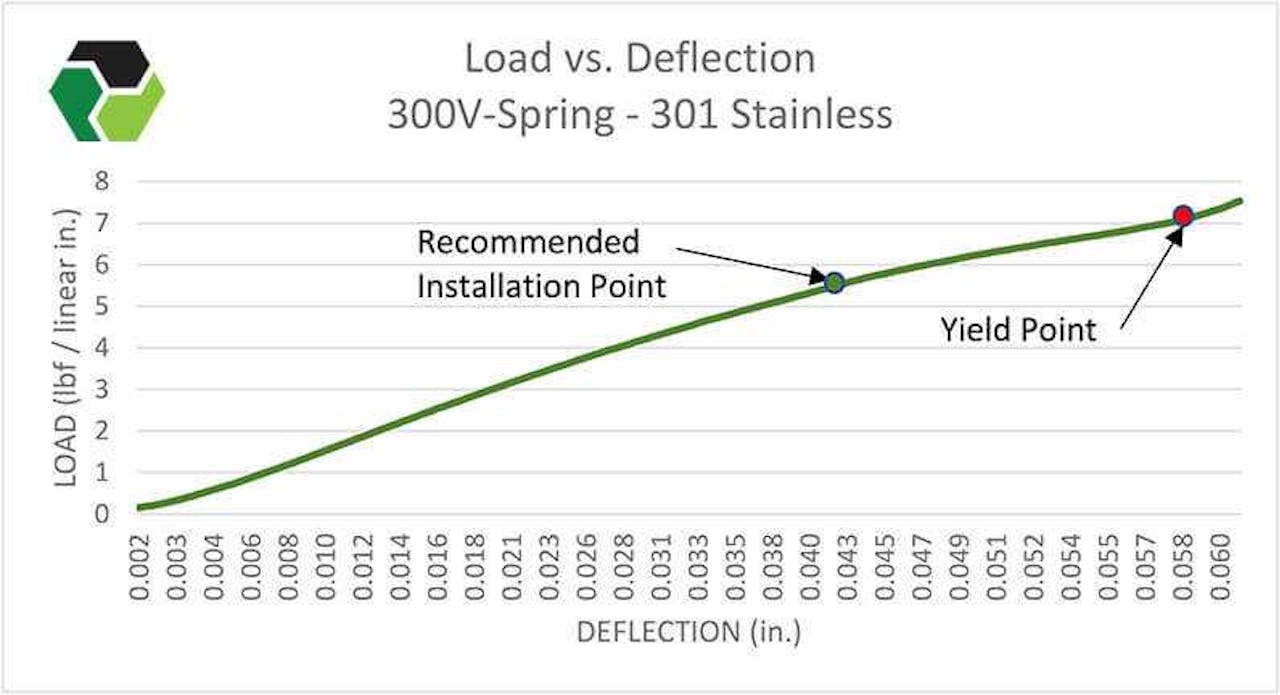

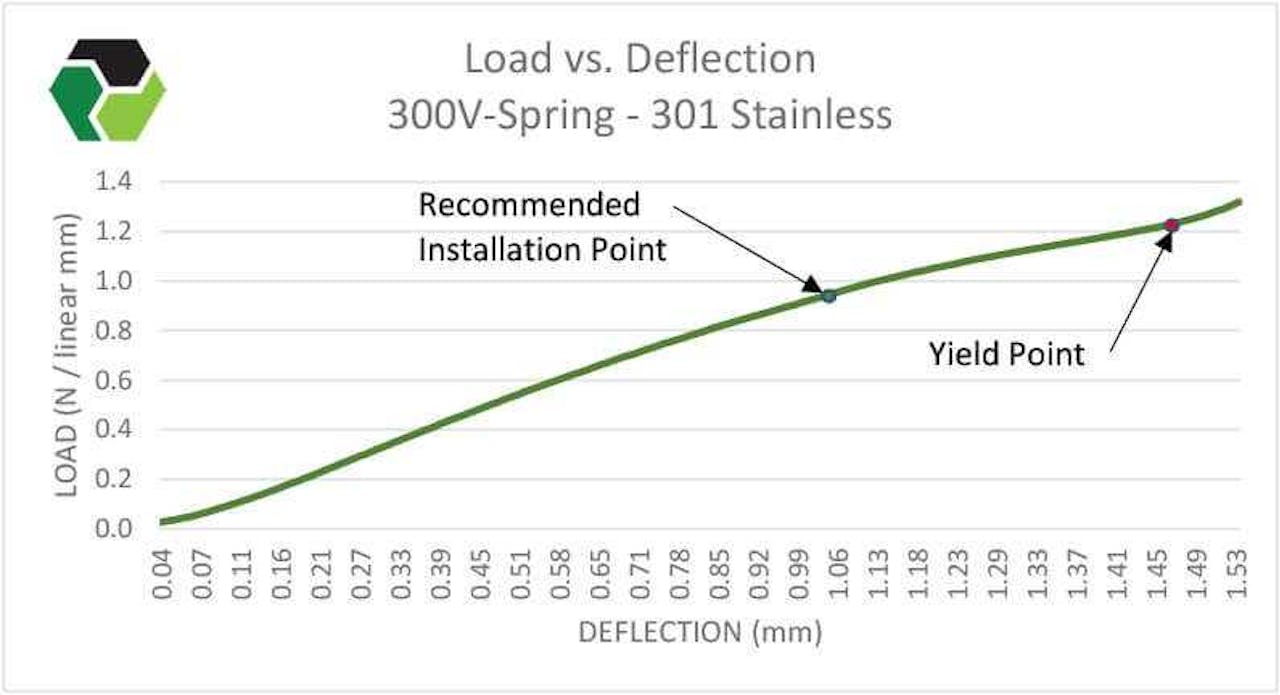

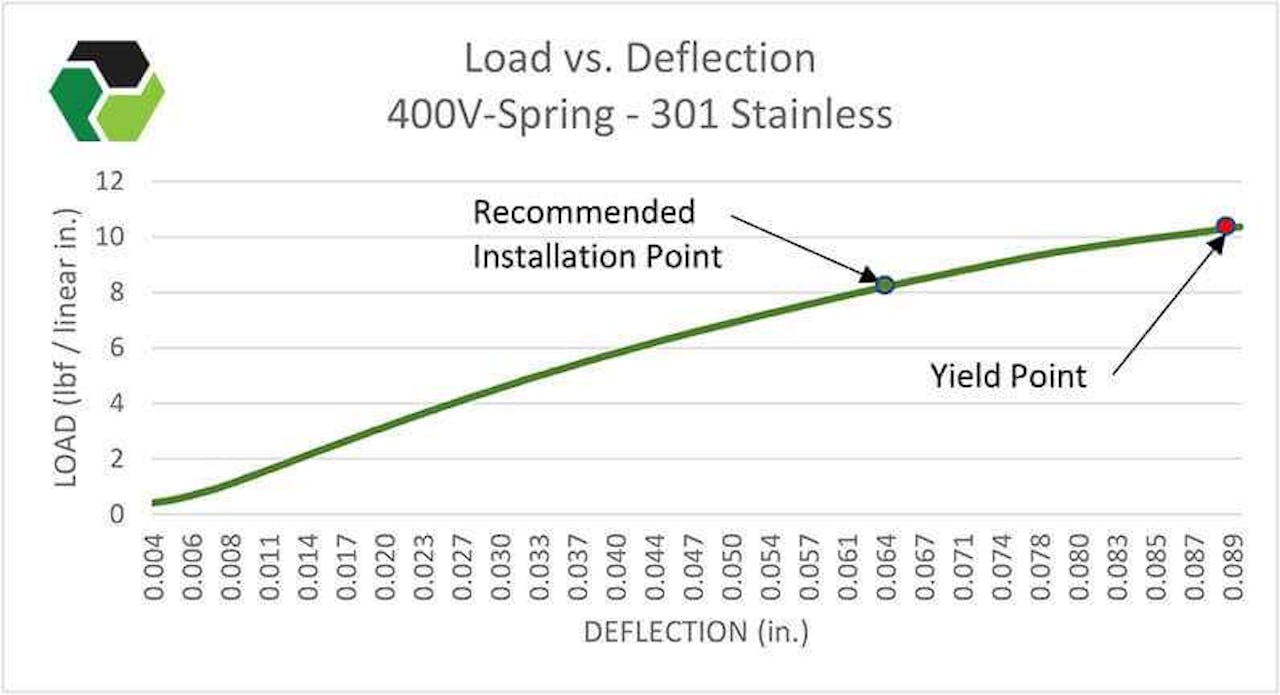

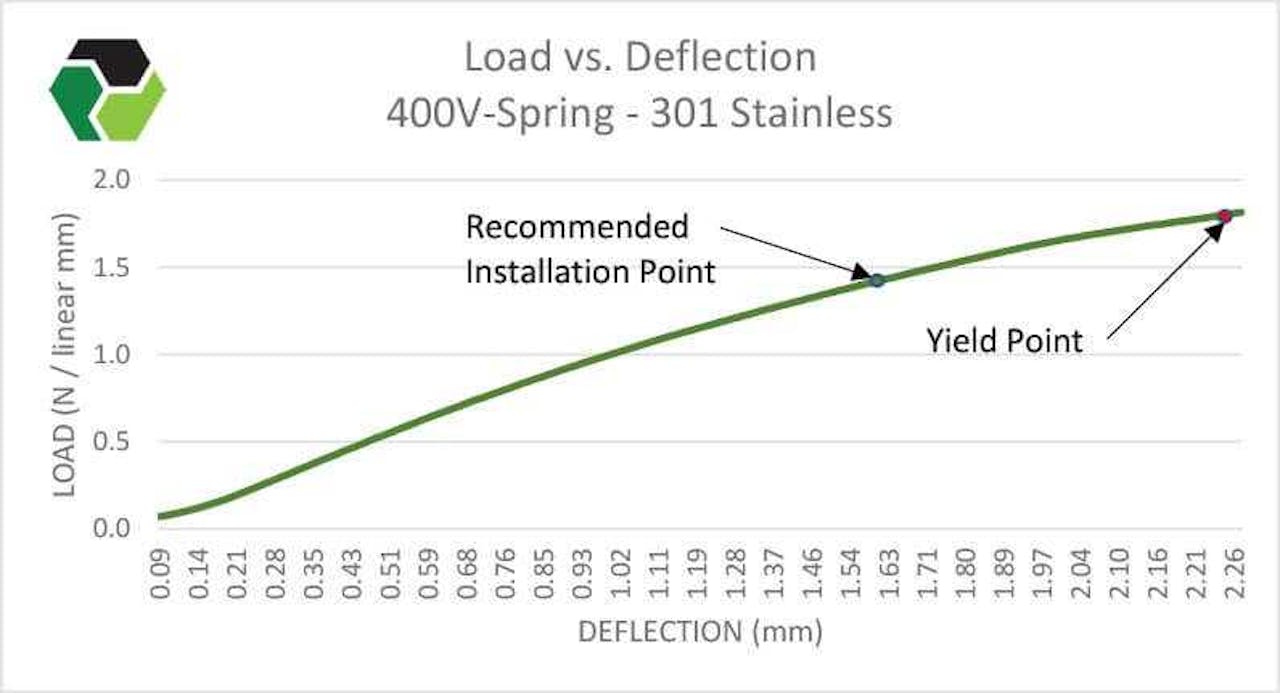

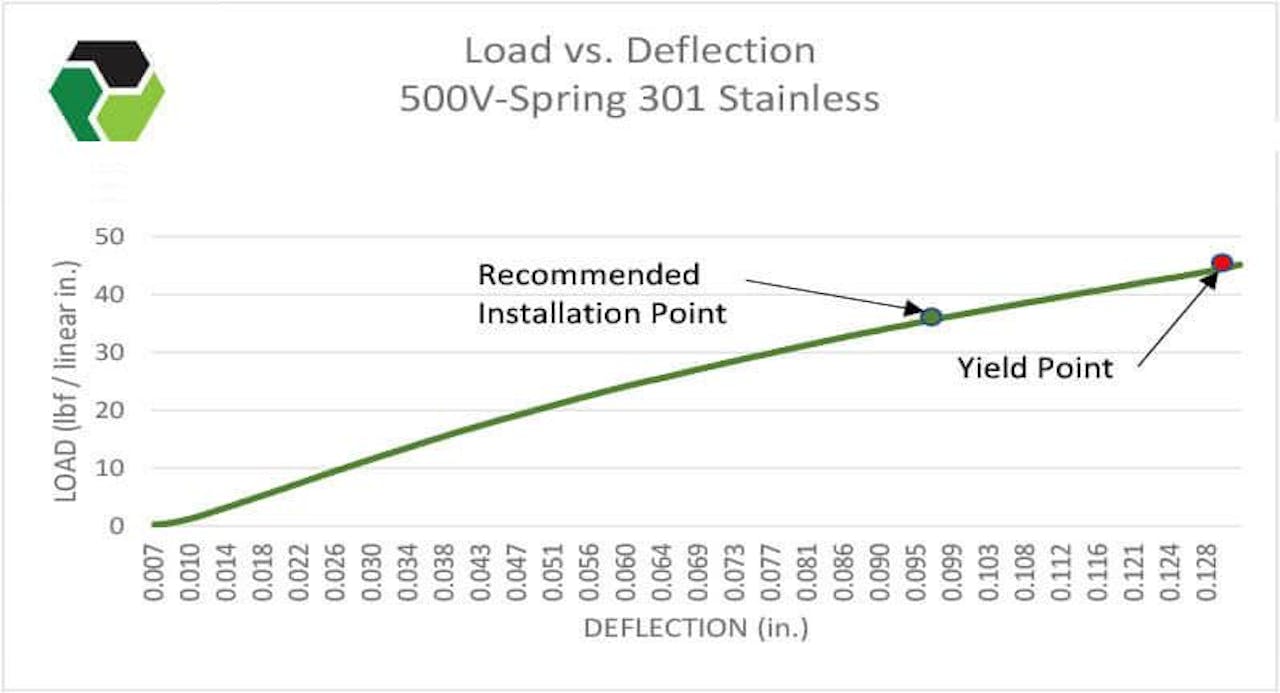

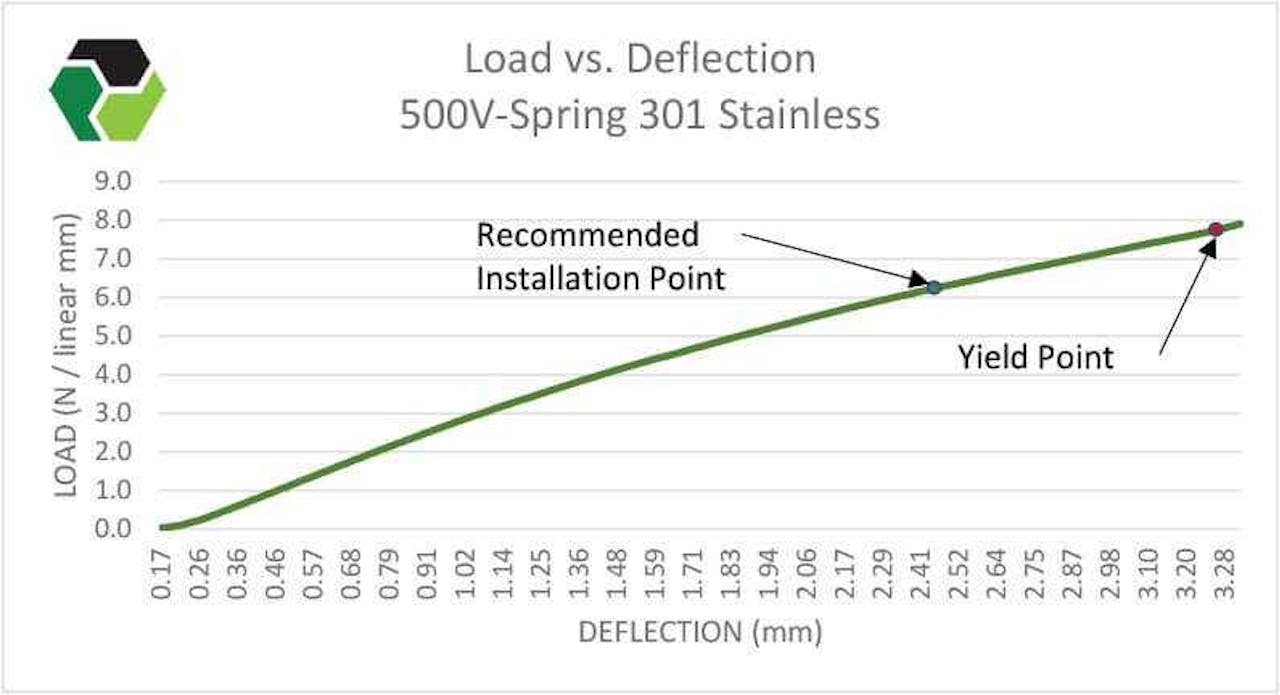

Stainless Steel V Spring Load Deflection Testing

V-Spring-000-S-1

V-Spring-100-S-2

V-Spring-200-S-2

V-Spring-300-S-2

V-Spring-400-S-1

V-Spring-500-S-1

Cavity Tool Drawings

Download V Spring Cavity Tool Drawings